- 1 Energy Efficiency and Power Consumption Analysis

- 2 Water Usage and Cleaning Requirements

- 3 Labor Costs and Maintenance Complexity

- 4 Integration with Downstream Sludge Drying Systems

- 5 Frequently Asked Questions (FAQ)

- 5.1 1. Can a sludge dewatering screw press handle oily sludge?

- 5.2 2. What is the typical lifespan of the screw in a stacked screw sludge dewatering machine?

- 5.3 3. How does the machine handle fluctuations in sludge concentration?

- 5.4 4. Does the low power consumption sludge dewatering system impact the output quality?

- 5.5 5. Is specialized training required to operate this sewage treatment equipment?

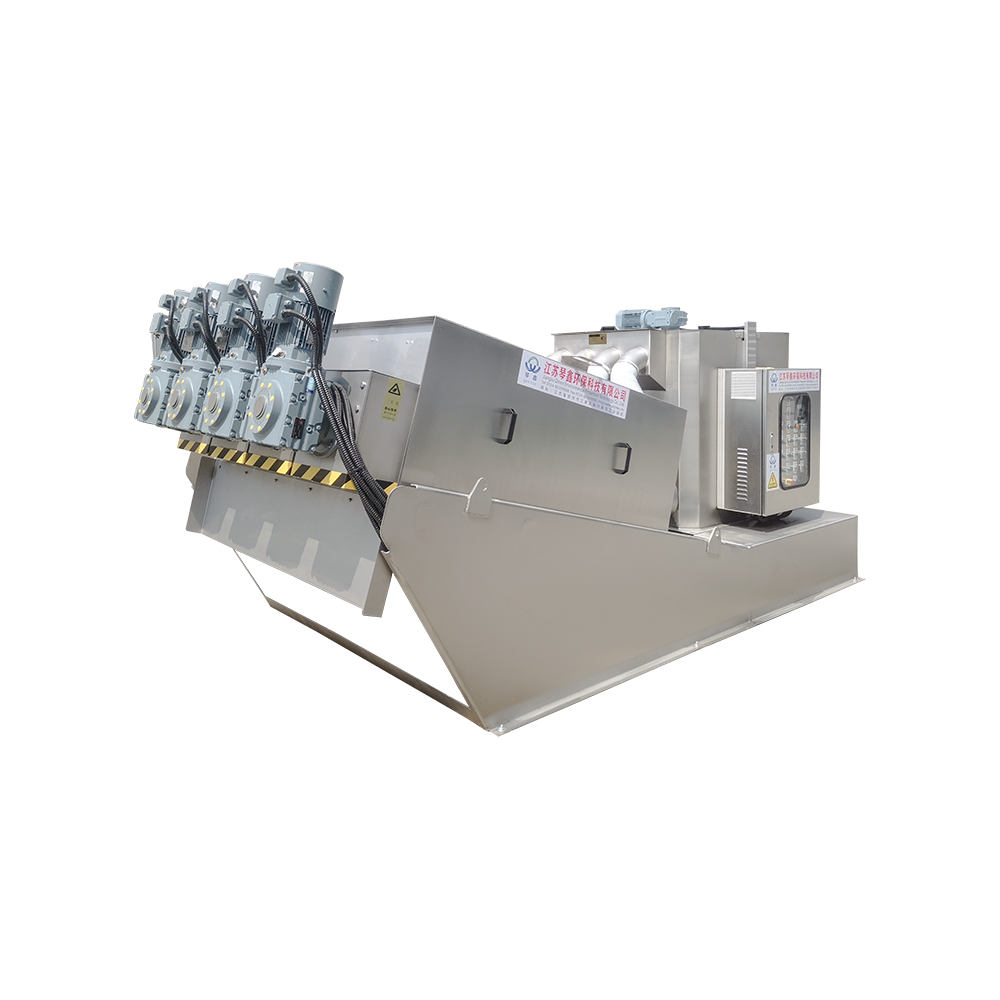

In the evolving landscape of wastewater management, industrial and municipal operators are increasingly scrutinizing the Total Cost of Ownership (TCO) for solids-handling equipment. While the belt filter press has historically been a common choice, the sludge dewatering screw press has emerged as a technologically superior alternative that addresses the critical pain points of high energy consumption, excessive water usage, and intensive maintenance. Yangzhou Qinxin Environmental Protection Technology Co., Ltd., an industry leader with multiple patents and AAA-level credit certification, specializes in advanced sewage treatment equipment tailored for food, petrochemical, and pharmaceutical sectors. Our stacked screw sludge dewatering machine represents the pinnacle of modern filtration engineering, designed to optimize cake dryness while drastically lowering operational overhead.

Energy Efficiency and Power Consumption Analysis

The fundamental mechanical advantage of a sludge dewatering screw press lies in its low rotational speed. Unlike belt presses that require high-tension rollers and high-pressure wash pumps, or centrifuges that operate at thousands of RPMs, a low power consumption sludge dewatering system operates at a mere 2-4 RPM. This slow-speed extrusion process significantly reduces kilowatt-hour (kWh) usage. According to the 2024 Global Water Technology Market Report by Global Water Intelligence (GWI), decentralized wastewater plants adopting screw press technology have reported energy savings of up to 85% compared to traditional belt press configurations, primarily due to the elimination of high-power hydraulic auxiliary components.

Source: Global Water Intelligence - Global Water Market 2024 Analysis

Comparison: Power Requirements for 24/7 Operation

While belt filter presses require significant electricity to maintain belt tension and drive high-volume wash water pumps, a sludge dewatering screw press utilizes a simple gear motor, resulting in a drastically lower power footprint.

| Mechanical Metric | Traditional Belt Filter Press | Sludge Dewatering Screw Press |

| Rotational Speed | Moderate (Continuous Belt Travel) | Ultra-Low (2-4 RPM) |

| Motor Load | High (Multiple auxiliary motors) | Minimal (Single main drive) |

| Energy Efficiency | Standard / Low | Exceptional (High Efficiency) |

Water Usage and Cleaning Requirements

Water consumption is a major hidden cost in dewatering operations. Belt presses require a continuous, high-pressure spray of "wash water" to prevent the filter belts from blinding (clogging). In contrast, a self-cleaning multi-disk screw press uses a dynamic and static ring structure that cleans itself automatically as the screw rotates. This mechanism eliminates the need for massive amounts of cleaning water. For operators in the chemical and tanning industries, implementing industrial wastewater sludge dewatering solutions based on screw technology can reduce wash water consumption by over 90%.

Comparison: Daily Wash Water Consumption

The difference in water intensity is stark: where a belt press consumes liters per minute continuously, the screw press requires only intermittent rinsing for a few minutes per hour.

| Operational Factor | Belt Filter Press | Stacked Screw Sludge Dewatering Machine |

| Cleaning Frequency | Continuous during operation | Intermittent (Timed Rinse) |

| Water Pressure Required | High Pressure (Recirculation pumps) | Low / Standard Pressure |

| Total Daily Water Usage | Very High (Thousands of Gallons) | Ultra-Low (Gallons) |

Labor Costs and Maintenance Complexity

Maintenance labor is often the highest variable cost for sewage treatment. Belt presses require constant operator monitoring to adjust belt tracking, tension, and chemical dosing. Furthermore, filter belts are susceptible to tearing and require frequent, expensive replacements. A fully automatic sludge screw press from Yangzhou Qinxin allows for unattended operation through integrated PAM integrated dosing devices. The 2025 technical standards released by the Water Environment Federation (WEF) highlight that modern "plug-and-play" dewatering modules have reduced manual labor hours by 60% compared to legacy pneumatic belt tensioning systems.

Source: Water Environment Federation - Wastewater Treatment Fundamentals 2025 Update

Comparison: Component Lifespan and Human Intervention

A screw press is engineered for durability, with wear-resistant parts that last for years, whereas belt presses necessitate frequent downtime for belt replacement and roller bearing maintenance.

| Maintenance Item | Belt Filter Press | Fully Automatic Sludge Screw Press |

| Consumables | Belts (6-9 months lifespan) | Tungsten-Carbide coated screw (Years) |

| Operator Oversight | Constant adjustments required | "Set and forget" automation |

| Ambient Environment | High Noise / Odor / Mist | Low Noise / Enclosed / Odor-free |

Integration with Downstream Sludge Drying Systems

Reducing operational costs also involves looking at the final disposal fee. The higher the cake dryness, the lower the weight of the sludge hauled to landfills. A sludge dewatering screw press provides consistent cake dryness across varying sludge types, from municipal bio-solids to oily petrochemical sludge. At Yangzhou Qinxin, we often integrate these machines with our sludge low-temperature drying systems. By achieving optimal pre-thickening and dewatering, we maximize the efficiency of the thermal drying phase, providing a comprehensive industrial wastewater sludge dewatering solutions package that minimizes disposal volume and environmental impact.

- Versatile Application: Effective for thin sludge (0.2% concentration) to high-solids influent.

- Compact Footprint: Requires significantly less floor space than belt presses or drying beds.

Frequently Asked Questions (FAQ)

1. Can a sludge dewatering screw press handle oily sludge?

Yes. Unlike belt presses where oil clogs the fabric, the self-cleaning multi-disk screw press is specifically designed to handle oily sludge in the food and petrochemical industries without blinding.

2. What is the typical lifespan of the screw in a stacked screw sludge dewatering machine?

Our stacked screw sludge dewatering machine components, especially the screw, are often treated with specialized hardening alloys, typically offering a service life of 5 to 10 years depending on the abrasiveness of the sludge.

3. How does the machine handle fluctuations in sludge concentration?

The fully automatic sludge screw press features a built-in thickening zone. This allows it to process sludge from very low concentrations (like those from an aerobic tank) without needing a separate thickener.

4. Does the low power consumption sludge dewatering system impact the output quality?

No. On the contrary, the slow and steady pressure increases within the screw barrel often result in more consistent cake dryness compared to the rapid compression of a belt press.

5. Is specialized training required to operate this sewage treatment equipment?

Because it is a fully automatic sludge screw press, operation is simplified through a PLC interface. Initial training is provided by Yangzhou Qinxin technicians, but day-to-day operation requires minimal manual input.

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP