- 1 The Mechanics of Cost Reduction in Agricultural Waste Streams

- 2 Operational Efficiency and Nutrient Management Strategies

- 3 Engineering Durability and System Customization

- 4 Financial Viability and Procurement Planning

- 5 Conclusion: Sustainable Wastewater Solutions with Yangzhou Qinxin

- 6 Frequently Asked Questions (FAQ)

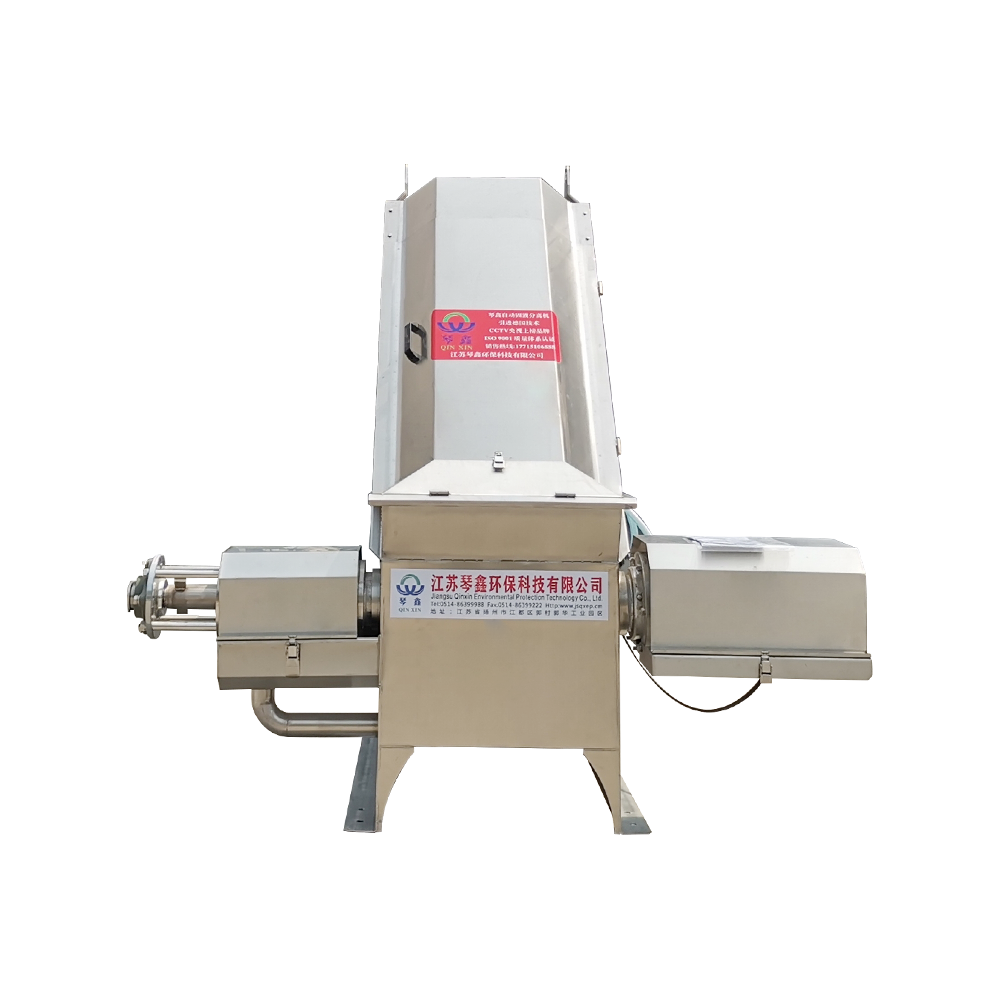

In the intensive dairy industry, waste management is no longer merely an environmental obligation but a significant operational expense that impacts the bottom line. Large-scale dairy farms generate massive volumes of slurry, which, if untreated, incurs high costs in storage, transport, and disposal. A screw-press solid liquid separator machine serves as a critical engineering intervention, mechanically dewatering the slurry to create two manageable streams: a nutrient-rich solid fiber and a liquid fraction suitable for irrigation or further treatment. Yangzhou Qinxin Environmental Protection Technology Co., Ltd., an industry-and-trade integrated enterprise, specializes in dewatering solutions that help municipal and agricultural sectors optimize these waste streams through high-end, patented technology.

The Mechanics of Cost Reduction in Agricultural Waste Streams

The primary cost-saving mechanism of a separator is the immediate reduction in the volume of liquid that must be stored in expensive lagoons. By extracting the solid fraction—often reaching 30% to 40% dry matter content—farms can maximize their existing storage capacity. According to the 2024-2025 Global Agricultural Technology Report by the Food and Agriculture Organization (FAO), integrated manure management systems can reduce logistical overhead by up to 25% through effective solid-liquid partitioning.

Source: FAO: Global Trends in Sustainable Manure Management 2024

Implementing an automatic solid liquid separator machine for manure for Labor Savings

Automation is essential for high-volume operations. An automatic solid liquid separator machine for manure features integrated sensors and PLC control systems that allow for continuous operation with minimal human intervention. Compared to manual or batch-processing systems, automated screw presses significantly lower man-hour requirements while ensuring a consistent output quality, regardless of the slurry's initial viscosity.

Operational Efficiency and Nutrient Management Strategies

Separation transforms "waste" into "assets." The solid fiber can be recycled as high-quality bedding for cows, eliminating the need to purchase external sand or straw. Simultaneously, the liquid fraction is easier to pump, reducing the energy consumption of irrigation systems.

Achieving Volume Reduction with a high efficiency solid liquid separator machine for aquaculture and Dairy

While often used in livestock, a high efficiency solid liquid separator machine for aquaculture or dairy applications must handle high-fiber loads without clogging. Efficiency is measured by the clarity of the filtrate and the dryness of the cake. High-efficiency systems utilize a precision-engineered screw pitch and wedge-wire screens to maximize the extraction of suspended solids, which is vital for preventing the sedimentation of lagoon systems.

Comparative Analysis: Raw Slurry Handling vs. Separated Waste Streams

The engineering transition from raw slurry to separated streams offers distinct advantages in transport costs and storage requirements. While raw slurry is heavy and difficult to move, separated liquid moves with minimal resistance, and dry solids can be stacked vertically to save space.

| Parameter | Raw Slurry Management | Separated Streams (Screw Press) |

| Storage Requirements | Large lagoons; frequent dredging required due to settling. | Reduced liquid volume; solids stored in dry piles. |

| Transport Logistics | Expensive; transporting 95%+ water content. | Efficient; solids transportable by truck; liquid by pump. |

| Resource Recovery | Low; difficult to apply nutrients precisely. | High; solids used for bedding/compost; liquid for fertigation. |

Engineering Durability and System Customization

Dairy manure is chemically aggressive, containing high levels of ammonia and organic acids. Consequently, the material selection for the solid liquid separator machine is paramount for long-term reliability. Yangzhou Qinxin adheres to strict quality management system certifications to ensure every unit exported to Southeast Asia and beyond withstands these corrosive environments.

Material Standards: Sourcing from stainless steel solid liquid separator machine manufacturers

Professional stainless steel solid liquid separator machine manufacturers utilize SUS304 or SUS316L for all contact parts. These alloys offer superior resistance to oxidative stress and abrasion from sand often found in dairy waste. Investing in high-grade steel reduces the frequency of component replacement, significantly lowering the Total Cost of Ownership (TCO) over the equipment's 10-15 year lifecycle.

Tailored Engineering: custom solid liquid separator machine systems for Scalability

No two dairy farms are identical in their waste profile. Through custom solid liquid separator machine systems, engineers can adjust the screen mesh size and screw rotation speed to match the specific livestock diet and flushing frequency. This bespoke approach ensures that municipal-grade technology is effectively adapted for the pharmaceutical, food, or aquaculture industries, providing a versatile solution for diverse sewage treatment needs.

Source: ISO 24510:2024 Activities relating to drinking water and wastewater services

Financial Viability and Procurement Planning

For B2B procurement, the initial capital expenditure (CAPEX) must be weighed against operational expenditure (OPEX) savings. A high-grade separator often pays for itself within 18 to 24 months solely through bedding savings and reduced lagoon maintenance.

Analyzing the industrial solid liquid separator machine price vs. Long-term ROI

While the industrial solid liquid separator machine price varies based on throughput capacity and automation levels, the return on investment (ROI) is driven by the 2025 shift toward "Circular Economy" models in agriculture. By converting manure into a dry, marketable compost or reusable bedding, the machine effectively transforms a liability into a revenue stream. As an AAA-level contract-oriented company, Yangzhou Qinxin provides reasonable quotations and professional technical support to ensure these financial goals are realized.

Conclusion: Sustainable Wastewater Solutions with Yangzhou Qinxin

Integrating a solid liquid separator machine into a dairy farm's infrastructure is a strategic move toward sustainability and cost-efficiency. By reducing waste volumes, recovering valuable resources, and utilizing custom solid liquid separator machine systems, farms can meet stringent environmental regulations while improving their profit margins. Yangzhou Qinxin Environmental Protection Technology Co., Ltd. remains committed to strong technical force and advanced service awareness to provide high-end sewage treatment equipment to the global market.

Frequently Asked Questions (FAQ)

- How much volume reduction can I expect? A screw-press solid liquid separator machine can typically remove 15-30% of total solids, leading to a significant reduction in the volume of liquid required for long-term storage.

- What is the typical maintenance schedule? For stainless steel solid liquid separator machine manufacturers, maintenance involves monthly lubrication of bearings and an annual inspection of the screw flight edges for wear.

- Can the solids really be used for cow bedding? Yes, when using a high efficiency solid liquid separator machine for aquaculture or dairy, the solids are dry enough to be used as green bedding, provided they are managed correctly to maintain hygiene.

- Is it difficult to install custom solid liquid separator machine systems? Not with professional support. Yangzhou Qinxin provides integrated design and technical services to ensure the equipment fits seamlessly into your existing manure handling infrastructure.

- Why does the industrial solid liquid separator machine price fluctuate? Prices are influenced by the cost of high-grade stainless steel and the complexity of the integrated PAM dosing or control systems required for your specific application.

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP