- 1 The Mechanical Relationship Between Mesh Size and Filtration Resistance

- 2 Sludge Characteristics and Particle Size Distribution

- 3 The Influence of Compression Force and Resistance

- 4 Qinxin's Commitment to Technical Excellence

- 5 Comparative Analysis: Determining the Optimal Dewatering Technology

- 6 Frequently Asked Questions (FAQ)

- 7 Industry References

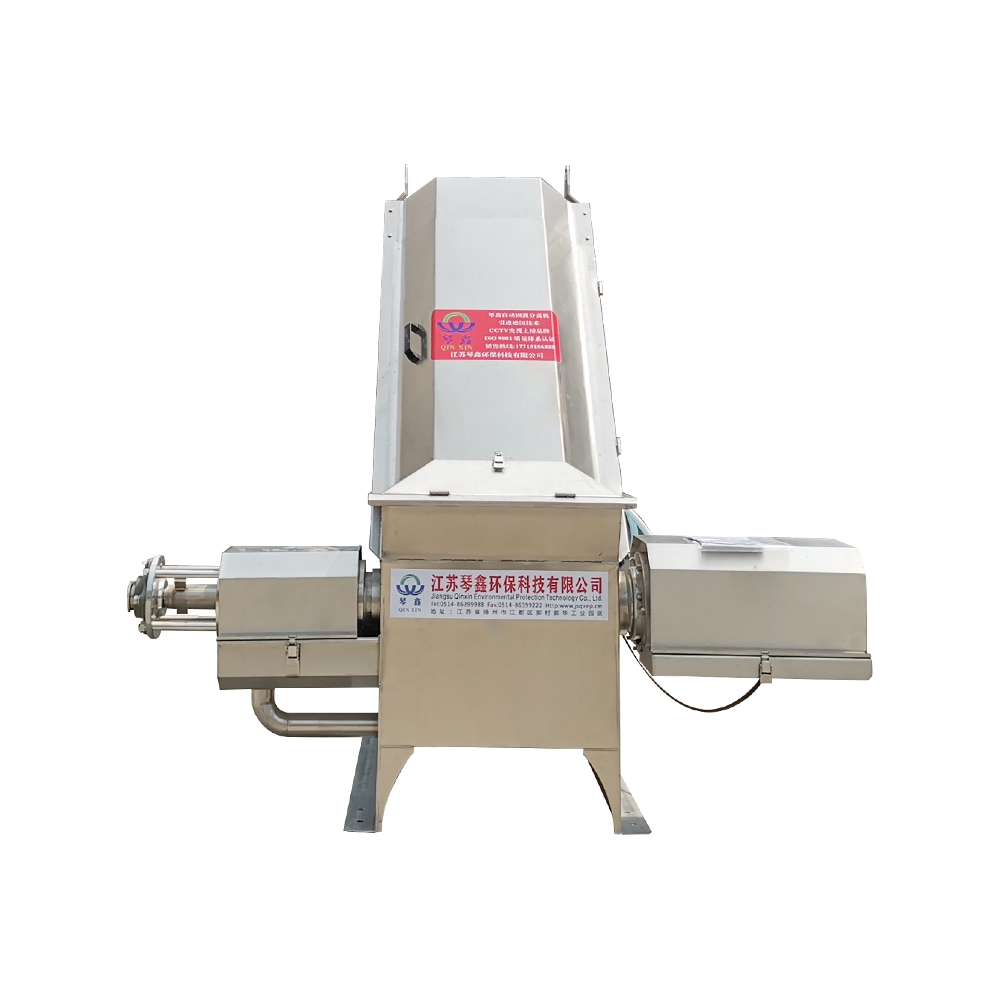

In the engineering of waste management and industrial process streams, the efficiency of a solid liquid separator machine is often measured by its ability to produce the highest possible dryness in the discharged solids, known as "cake moisture." Achieving this requires a precise calibration of mechanical pressure and hydraulic conductivity. Yangzhou Qinxin Environmental Protection Technology Co., Ltd., an industry-and-trade integrated enterprise, specializes in the R&D of high-end environmental equipment including stacked screw sludge dewatering machines and solid-liquid separators. With numerous patents and AAA-level credit certifications, we serve diverse sectors from petrochemicals to aquaculture, ensuring our industrial wastewater dewatering equipment meets the rigorous standards of the global market.

The Mechanical Relationship Between Mesh Size and Filtration Resistance

The screen mesh size is the primary determinant of the filtration boundary. Selecting a mesh that is too fine increases filtration resistance and may lead to surface blinding, whereas a mesh that is too coarse allows fine suspended solids to bypass the separator. In efficient manure solid liquid separation, the goal is to create a "filter cake" that acts as its own secondary filtration layer. While finer meshes capture more solids, they can trap interstitial water, whereas coarser meshes allow for faster drainage but risk lower solids recovery.

| Screen Mesh Characteristic | Fine Mesh (<0.3mm) | Coarse Mesh (>0.7mm) |

| Filtration Speed | Slower due to higher resistance | Rapid initial hydraulic discharge |

| Solids Capture Rate | High (Captures microscopic flocs) | Lower (Requires high fibrous content) |

| Cake Moisture Potential | Higher (Capillary water retention) | Lower (Enhanced gravity drainage) |

Sludge Characteristics and Particle Size Distribution

The physical nature of the raw material—whether it is municipal sludge, food waste, or aquaculture manure—dictates the mesh requirements. For instance, a manure solid liquid separator price evaluation must consider the specific livestock waste profile; cow manure with high fiber content permits a larger mesh than pig manure with high colloidal content. When using screw press solid liquid separator for farming, the fiber-to-colloid ratio determines if the solids can form a structural "plug" against the screen, which is essential for mechanical compression and moisture expression.

Comparative Analysis by Industry Stream

Industrial sludges behave differently under mechanical stress depending on their origin and chemical pretreatment, such as the use of a PAM integrated dosing device to facilitate flocculation.

| Industry | Typical Mesh Size | Reasoning for Choice |

| Aquaculture (Manure) | 0.5mm - 1.0mm | High fiber content provides self-filtering structure. |

| Food & Beverage | 0.3mm - 0.5mm | Organic particles require moderate retention for dryness. |

| Chemical / Paper | 0.1mm - 0.3mm | Fine chemical flocs require high retention rates. |

The Influence of Compression Force and Resistance

Beyond the mesh itself, the moisture level is influenced by the internal pressure of the solid liquid separator machine. If the mesh is too large, the increased pressure will simply force solids through the screen (the "extrusion" effect) rather than squeezing water out of the cake. Engineers must balance the torque of the screw and the resistance of the weighted discharge outlet. Our stainless steel solid liquid separator designs integrate high-strength wedge-wire screens that withstand high-pressure differentials without deforming, a common issue in lower-grade equipment.

- Wedge-Wire Advantage: The V-shaped profile of the screen wires reduces the contact area at the aperture, minimizing blinding and allowing for more efficient "backwashing" during operation.

- Pre-thickening: For low-concentration sludges, our stacked screw dewatering systems utilize a thickening zone before the main compression zone to optimize mesh performance.

- Material Selection: Utilizing SUS304 or SUS316 ensures that the mesh size remains constant over thousands of hours of operation despite the abrasive nature of industrial sludges.

Qinxin's Commitment to Technical Excellence

At Yangzhou Qinxin Environmental Protection Technology Co., Ltd., we combine years of practical experience with a dedicated technical team. Our sewage treatment equipment is designed based on a strict management process that has won the trust of customers in Southeast Asia and beyond. By offering tailored solutions—ranging from sludge low-temperature drying systems to optimized separators—we ensure that each client achieves the lowest possible cake moisture, reducing secondary disposal costs and improving resource recovery.

Comparative Analysis: Determining the Optimal Dewatering Technology

While both technologies utilize a screw-driven mechanical compression principle, their internal architectures are designed for different feed concentrations and solid structures. Yangzhou Qinxin utilizes advanced R&D and practical field experience to manufacture both systems, ensuring high-grade solutions for municipal and industrial clients.

1. Internal Architecture and Clog Resistance

The stacked screw sludge dewatering machine consists of a screw shaft rotating through a cylinder of alternating "fixed" and "moving" rings. The microscopic movement of the rings continuously cleans the filtration gaps, making it virtually clog-free. In contrast, a screw press solid liquid separator for farming uses a fixed wedge-wire screen, which relies on the abrasive nature of fibrous solids to keep the mesh clear.

| Feature | Stacked Screw Dewatering Machine | Screw Press Solid Liquid Separator |

| Cleaning Mechanism | Self-cleaning moving rings | External high-pressure spray/fibrous abrasion |

| Handling of Oily Sludge | Excellent (Non-clogging) | Poor (Prone to screen blinding) |

| Feed Concentration | Low to Medium (2,000mg/L - 50,000mg/L) | High (Usually > 3% - 10% solids) |

2. Performance in Specific Industrial Streams

A solid liquid separator machine is often the first choice for aquaculture and food processing where large, fibrous particles are present. However, for biological municipal sludge or chemical flocs—which are often slimy and low in fiber—the industrial wastewater dewatering equipment of choice is the stacked screw, as it can thicken and dewater in a single unit.

- Municipal/Chemical Sludge: Requires the thickening zone of a stacked screw to handle low-inlet concentrations.

- Livestock Manure (Cow/Pig): The efficient manure solid liquid separation provided by a screw press is more economical due to the higher throughput capacity for high-solids feeds.

- Petrochemical/Printing: Stacked screw systems are preferred due to the presence of oils and polymers that would otherwise blind a static screen.

3. Operational Efficiency and Maintenance

From an engineering perspective, the manure solid liquid separator price is typically lower than a stacked screw unit, making it the better B2B choice for high-volume, low-complexity agricultural waste. However, for high-end municipal and medical applications, the stacked screw's low power consumption (often < 0.5 kWh/kg-DS) and minimal water usage for rinsing provide a higher long-term ROI.

| Metric | Stacked Screw System | Screw Press Separator |

| Energy Consumption | Very Low (Slow RPM) | Moderate (Higher torque requirements) |

| Wear Part Life | High (Rings protect the screw) | Moderate (Direct contact with screen) |

| Automation Level | Fully Automatic (24/7) | High (But requires screen monitoring) |

Conclusion for Procurement Teams

If your project involves high-concentration fibrous waste (like raw manure), a screw press solid liquid separator for farming is your most efficient choice. If you are dealing with low-concentration, oily, or biological sludge in municipal or chemical sectors, a stacked screw sludge dewatering machine from Qinxin will provide superior performance and lower maintenance.

Frequently Asked Questions (FAQ)

- Q1: Does a smaller mesh always result in drier solids?

A: Not necessarily. While a smaller mesh captures more fines, it can restrict water flow and trap moisture within the cake. The "optimal" size is the largest mesh that still retains sufficient solids to form a dry, compressed plug. - Q2: How often should the screen mesh be replaced in a solid liquid separator?

A: This depends on the abrasiveness of the material. However, high-quality stainless steel wedge-wire screens in our solid liquid separator machine units typically last 2-3 years under standard operating conditions. - Q3: Can I process different types of waste with the same mesh?

A: It is possible, but efficiency will vary. We recommend interchangeable screens if your facility processes significantly different waste streams to maintain efficient manure solid liquid separation. - Q4: How does chemical dosing affect the mesh size choice?

A: Proper dosing with a PAM integrated dosing device creates larger, stronger flocs. This allows you to use a slightly larger mesh size, which improves drainage and results in lower cake moisture. - Q5: Why is cake moisture so important for B2B buyers?

A: Lower moisture reduces the weight and volume of waste, directly lowering transportation and landfill costs. It also makes the solids easier to compost or use as fuel in biomass systems.

Industry References

- ISO 9001:2015 - Quality Management Systems in Environmental Equipment Production.

- Water Environment Federation (WEF) - Manual of Practice: Sludge Dewatering and Management.

- Journal of Water Process Engineering - Factors affecting the dewaterability of organic sludges.

- Environmental Protection Agency (EPA) - Guide to Solid-Liquid Separation Technology.

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP