- 1 1. Overcoming the Clogging Challenge: The Self-Cleaning Mechanism

- 2 2. Processing Low-Concentration Sludge: Built-in Thickening

- 3 3. Enhancing Performance: Flocculation and Dosing Systems

- 4 4. Analyzing Longevity: Screw Press Maintenance and Wear Resistance

- 5 Frequently Asked Questions (FAQ)

- 5.0.1 1. Does the oil in the sludge affect the dryness of the final cake?

- 5.0.2 2. Can a screw press replace a traditional DAF (Dissolved Air Flotation) system?

- 5.0.3 3. How often do the moving rings need to be replaced?

- 5.0.4 4. Is the screw press suitable for food industry sludge (brewing/dairy)?

- 5.0.5 5. How does low temperature affect sludge dewatering?

- 6 Industry References

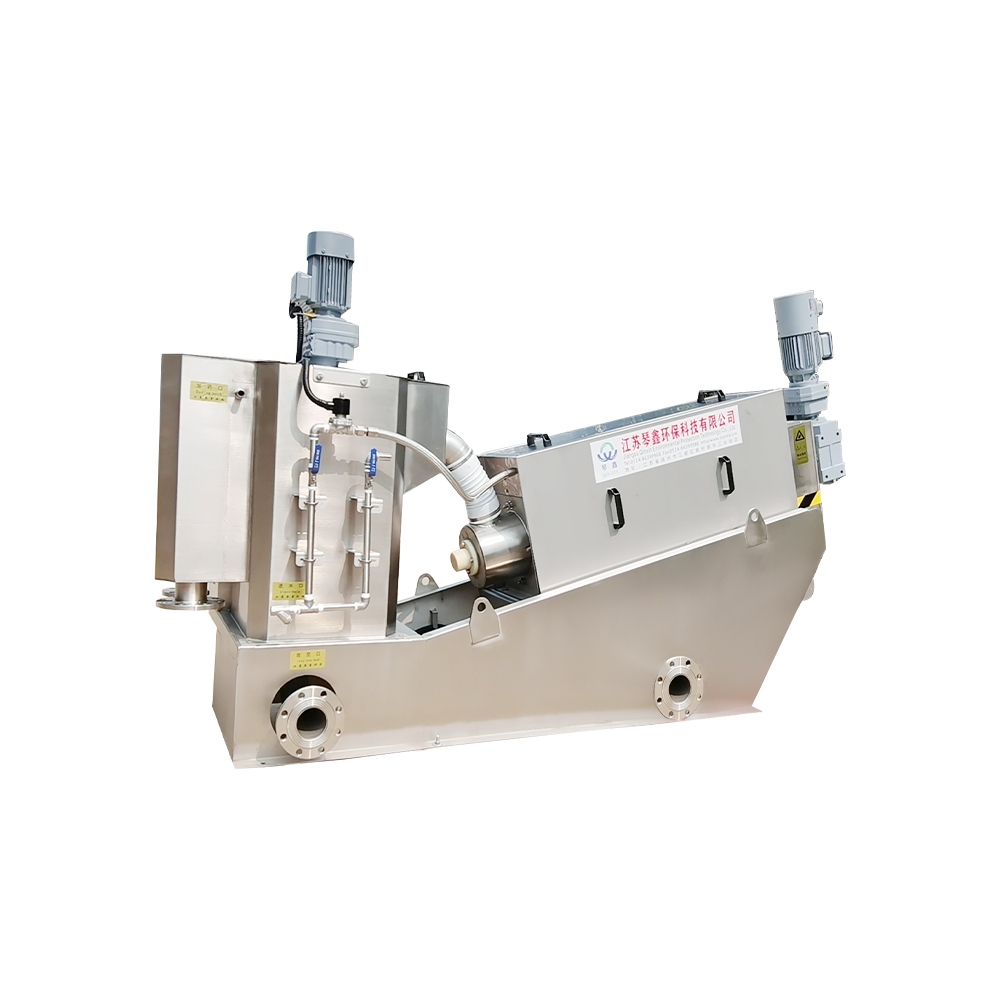

In the complex landscape of industrial wastewater management, two types of sludge present significant challenges for traditional filtration systems: oily sludge from petrochemical or food processing, and low-concentration sludge often found in initial settling tanks. The sludge dewatering screw press has revolutionized this sector by offering a continuous, non-clogging solution. Yangzhou Qinxin Environmental Protection Technology Co., Ltd., an industry leader in research and development, provides advanced stacked screw dewatering machines designed to meet the rigorous demands of municipal, chemical, and pharmaceutical industries. Our AAA-level contract-oriented enterprise ensures that high-end technology is accessible for global sewage treatment challenges.

1. Overcoming the Clogging Challenge: The Self-Cleaning Mechanism

The most persistent question among environmental engineers is how a sludge dewatering screw press prevents clogging with oily sludge. Traditional belt presses or centrifuges often struggle with oily residues because the grease adheres to filter cloths or requires high-speed centrifugal force that can lead to maintenance intensity. A sludge dewatering screw press utilizes a unique structure of "fixed rings" and "moving rings" that create a self-cleaning gap. As the screw shaft rotates, it continuously cleans the gaps between the rings, preventing the oily solids from blinding the filtration area.

While belt presses require high-volume wash water to keep the belts clean, the screw press consumes minimal water because its mechanical movement prevents the buildup of "sticky" sludge components.

| Technical Feature | Sludge Dewatering Screw Press | Traditional Belt Filter Press |

| Clogging Resistance | High (Self-cleaning moving rings) | Low (Requires constant high-pressure washing) |

| Handling Oily Material | Excellent (Non-adhesive operation) | Poor (Grease blinds the filter cloth) |

| Wash Water Usage | Extremely Low | High (To prevent belt blinding) |

2. Processing Low-Concentration Sludge: Built-in Thickening

Many operators ask, what is the minimum sludge concentration for a screw press? Traditional dewatering equipment usually requires a separate thickening tank to increase solids concentration to 1% or 2% before dewatering can begin. However, a modern sludge dewatering screw press often features an integrated "thickening zone" at the intake. This allows it to handle sludge as thin as 2000mg/L directly from the aeration tank. Yangzhou Qinxin Environmental Protection Technology Co., Ltd. specializes in these integrated systems, reducing the footprint and capital cost of wastewater plants by eliminating the need for bulky thickening infrastructure.

Compared to centrifuges, which require high energy to settle low-density solids, the screw press uses gravity and slow-speed mechanical thickening to achieve a stable cake dryness even with dilute feed.

| Operational Aspect | Direct Feed Screw Press | Conventional Centrifuge |

| Initial Concentration Requirement | Low (0.2% - 0.5%) | High (Typically > 1.5%) |

| Pre-Thickening Equipment | Not Required (Integrated) | Required (Settling tanks or GBT) |

| Energy Consumption | Low (0.1 - 0.5 kWh/kg-DS) | High (Due to high RPM requirements) |

3. Enhancing Performance: Flocculation and Dosing Systems

To ensure high capture rates in oily or dilute environments, why is polymer dosing critical for screw press efficiency? Oily particles tend to be emulsified and stable; therefore, they require a high-quality PAM integrated dosing device to create robust flocs. Yangzhou Qinxin Environmental Protection Technology Co., Ltd. provides these supporting products to ensure the sludge enters the sludge dewatering screw press with the ideal structure for mechanical compression. Proper flocculation ensures that the "free water" is released early in the thickening zone, allowing the pressure zone to maximize cake dryness.

- Chemical Synergy: The use of specific cationic polyacrylamide (PAM) helps break oil-in-water emulsions.

- Automated Control: Our systems synchronize dosing speed with the screw press throughput for optimized chemical usage.

- Patent-Backed Design: Our research into solid-liquid separators ensures maximum solids recovery even in complex pharmaceutical wastewater.

4. Analyzing Longevity: Screw Press Maintenance and Wear Resistance

Engineers frequently inquire about how to maintain a sludge dewatering screw press when dealing with abrasive or chemically aggressive industrial sludge. Unlike high-speed equipment, the screw press operates at very low speeds (usually 2-4 RPM). This dramatically reduces mechanical wear and noise. For industries like papermaking or aquaculture, where sludge can be corrosive, the stainless steel construction and specialized surface treatments of the rings ensure a long service life. Yangzhou Qinxin's adherence to ISO quality and environmental management systems guarantees that every sludge dewatering screw press is built for durability in "high-end" global markets.

Frequently Asked Questions (FAQ)

1. Does the oil in the sludge affect the dryness of the final cake?

While oil itself cannot be "dewatered" in the same way as water, the sludge dewatering screw press effectively captures the oil-bound solids. The final cake dryness depends on the ratio of organic to inorganic solids, but generally ranges from 20% to 25% for oily industrial sludge.

2. Can a screw press replace a traditional DAF (Dissolved Air Flotation) system?

No, they serve different purposes. A DAF removes oil and suspended solids from the water stream, while the sludge dewatering screw press dewaters the concentrated sludge generated by the DAF. They are often used together in petrochemical wastewater treatment.

3. How often do the moving rings need to be replaced?

Under normal operating conditions and proper maintenance, the rings and screw shaft of a high-quality sludge dewatering screw press from Yangzhou Qinxin can last for several years before requiring inspection or replacement.

4. Is the screw press suitable for food industry sludge (brewing/dairy)?

Absolutely. It is the preferred choice because it handles the high grease content of food sludge without clogging, and its low noise level is ideal for indoor food processing environments.

5. How does low temperature affect sludge dewatering?

Low temperatures can slow down the flocculation process. For optimal results in cold climates, Yangzhou Qinxin recommends our sludge low-temperature drying systems as a secondary stage to achieve even lower moisture content after the initial dewatering.

Industry References

- ISO 9001:2015 - Quality Management Systems — Requirements for Environmental Equipment.

- WEF (Water Environment Federation) Manual of Practice No. 8: Design of Municipal Wastewater Treatment Plants.

- Research on "Mechanical Dewatering of Oily Sludge Using Screw Press Technology" - Environmental Science & Engineering Archives.

- Technical Standards of Yangzhou Qinxin Environmental Protection Technology Co., Ltd. (2010-2026).

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP