- 1 Sludge Treatment Challenges in Modern Wastewater Management

- 2 Understanding the Screw Press Dewatering Machine Technology

- 3 A New Era for Sludge Dewatering: How the Screw Press Dewatering Machine is Changing the Game

- 4 Environmental and Economic Benefits of Screw Press Dewatering Machines

- 5 Key Factors to Consider When Choosing a Screw Press Dewatering Machine

Sludge Treatment Challenges in Modern Wastewater Management

In modern wastewater treatment, sludge management is a critical process that directly impacts operational efficiency and compliance with environmental regulations. Sludge typically contains a high water content, along with organic matter, inorganic particles, and microorganisms, making it difficult and costly to handle.

1. High Water Content and Dewatering Difficulty

- Raw sludge often contains 95%–99% water, resulting in a large volume and high transportation/disposal costs.

- Even after treatment with traditional dewatering equipment, water content often remains 75%–85%, which is still above the ideal range.

Water Content Comparison by Process

| Process Type | Typical Post-Treatment Water Content | Notes |

|---|---|---|

| Gravity Thickening | 94%–96% | Only suitable for thickening |

| Belt Filter Press | 78%–85% | Large footprint, requires flocculants |

| Centrifugal Dewatering | 75%–80% | High energy use, high noise |

| Screw Press Dewatering Machine | 70%–75% | Compact footprint, energy-saving low speed |

2. High Operating Costs

- Energy use: Some mechanical dewatering devices require 10–20 kWh per ton of sludge.

- Chemical reliance: Use of flocculants and filter aids increases cost and risk of secondary pollution.

- Maintenance: High-speed equipment wears quickly and requires frequent parts replacement.

3. Stricter Environmental Regulations

- Limits on final sludge water content, heavy metals, and organics are becoming more stringent.

- High water content increases landfill or incineration difficulty and leachate risk.

4. Space Limitations

- Traditional systems require a large footprint, making them unsuitable for urban facilities.

- Compact solutions like the Screw Press Dewatering Machine are preferred in space-constrained plants.

5. Continuous Operation Requirements

- Many facilities require 24/7 operation with minimal downtime, which demands reliable, low-maintenance equipment.

Understanding the Screw Press Dewatering Machine Technology

The Screw Press Dewatering Machine is a low-speed, high-efficiency solid-liquid separation device widely used in sludge treatment. It uses continuous screw compression combined with adjustable back pressure to achieve stable dewatering.

1. Working Principle

- Sludge Feeding – Thickened sludge enters the inlet.

- Flocculation – Flocculants may be added before or at the inlet to form larger flocs.

- Screw Compression – The screw slowly rotates, pushing sludge toward the outlet; pitch decreases and compression increases.

- Water Discharge – Water passes through fixed filter gaps or screens.

- Back Pressure Adjustment – The outlet pressure plate controls cake dryness.

2. Key Components

- Feeding zone

- Screw pressing zone

- Filtration zone (screen plates)

- Sludge discharge port & back pressure device

- Drive system (low-speed motor with reducer)

3. Technical Comparison

| Indicator | Screw Press Dewatering Machine | Centrifugal Dewatering | Belt Filter Press |

|---|---|---|---|

| Post-treatment water content | 70%–75% | 75%–80% | 78%–85% |

| Operating speed | 0.1–1 rpm | 1,000–3,000 rpm | 2–10 m/min |

| Energy use (kWh/ton) | 1–3 | 10–20 | 4–8 |

| Footprint | Small | Medium | Large |

| Noise level (dB) | 50–60 | 80–95 | 70–85 |

| Maintenance frequency | Low | High | Medium |

| Sludge types | Oily, organic, mixed sludge | Various | Various |

4. Advantages

- Energy-saving and low wear

- High automation and minimal operator intervention

- Wide sludge applicability

A New Era for Sludge Dewatering: How the Screw Press Dewatering Machine is Changing the Game

The sludge dewatering industry is undergoing transformation, with the Screw Press Dewatering Machine at its core. It addresses the shortcomings of traditional systems—high energy use, frequent maintenance, and large footprints—while offering improved efficiency and cost savings.

Performance Comparison

| Indicator | Screw Press Dewatering Machine | Centrifugal Dewatering | Belt Filter Press |

|---|---|---|---|

| Water content reduction | 70%–75% | 75%–80% | 78%–85% |

| Energy use (kWh/ton) | 1–3 | 10–20 | 4–8 |

| Footprint | Small | Medium | Large |

| Noise level (dB) | 50–60 | 80–95 | 70–85 |

| Operator requirement | Low (automated) | Medium | Medium |

Key Impacts

- Municipal plants – Ideal for retrofits or expansions in limited spaces.

- Industrial wastewater – Handles viscous, oily, or high-solids sludge effectively.

- Sustainability – Aligns with energy conservation and resource recovery goals.

Environmental and Economic Benefits of Screw Press Dewatering Machines

1. Environmental Benefits

- Volume Reduction: Cuts sludge volume by 60%–80% through lower water content.

- Reduced Pollution: Lower leachate generation and minimized chemical use.

- Energy Efficiency: 1–3 kWh/ton versus 10–20 kWh/ton for centrifuges.

2. Economic Benefits

- Lower Operating Costs: Less energy and fewer chemicals.

- Reduced Maintenance: 6–12 month maintenance intervals.

- Shorter Payback: ROI achieved in 2–4 years.

Environmental & Economic Comparison

| Indicator | Screw Press Dewatering Machine | Centrifugal Dewatering | Belt Filter Press |

|---|---|---|---|

| Water content | 70%–75% | 75%–80% | 78%–85% |

| Energy use (kWh/ton) | 1–3 | 10–20 | 4–8 |

| Annual maintenance frequency | 1–2 | 4–6 | 3–5 |

| Chemical cost (relative) | Low | Medium | Medium |

| Transport cost (relative) | Low | Medium | High |

| Payback period (years) | 2–4 | 4–6 | 3–5 |

Key Factors to Consider When Choosing a Screw Press Dewatering Machine

When selecting a Screw Press Dewatering Machine, consider not only dewatering performance but also cost, suitability, and supplier capability.

1. Capacity & Suitability

- Match sludge type and daily volume to the machine size.

Reference Capacities

| Size Category | Capacity Range (m³/h) | Suitable Solids (%) | Footprint (m²) |

|---|---|---|---|

| Small | 0.5–5 | 0.2–2.0 | 2–4 |

| Medium | 5–20 | 0.2–3.0 | 5–8 |

| Large | 20–50+ | 0.2–3.5 | 8–12 |

2. Energy Use & Costs

- Lower-speed systems use 1–3 kWh/ton, reducing operating costs.

3. Materials & Durability

- Use corrosion-resistant stainless steel for high-acid or oily sludge.

4. Automation & Maintenance

- Automatic cleaning and PLC remote monitoring improve efficiency.

5. Supplier Capability – Yangzhou Qinxin Environmental Protection Technology Co., Ltd.

- An integrated R&D, manufacturing, and sales enterprise specializing in environmental protection equipment.

- Main products: stacked screw sludge dewatering machines, PAM integrated dosing devices, sludge low-temperature drying systems, solid-liquid separators, and other wastewater treatment equipment.

- Service industries: municipal, food, petrochemical, aquaculture, papermaking, leather, brewing, printing and dyeing, chemical, pharmaceutical, and medical.

- Holds multiple patents and certifications in quality, environmental management, and occupational health and safety.

- Strong technical team, strict quality control, and advanced service awareness.

6. Cost-effectiveness & ROI

- Quality systems may have higher upfront costs but achieve payback in 2–4 years through energy savings, reduced maintenance, and lower chemical use.

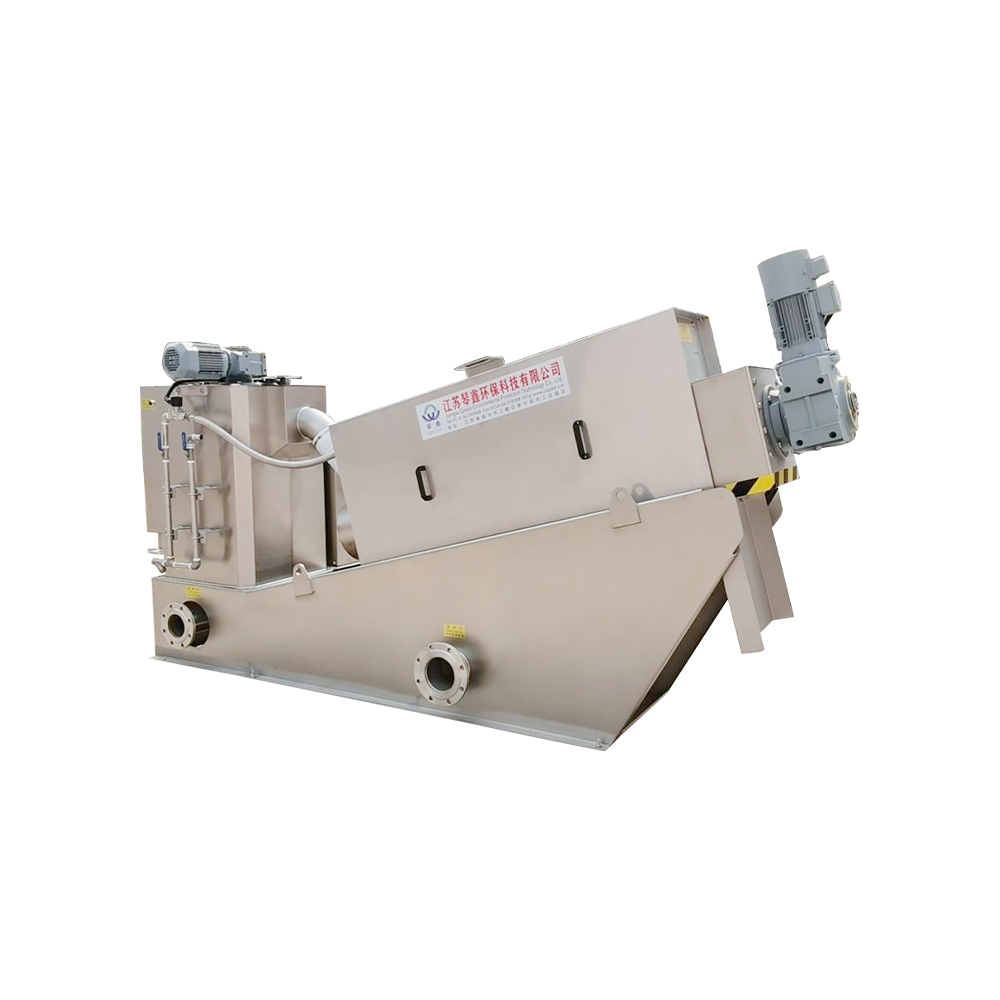

Eco-friendly Solid-Liquid Separation Spiral Screw Sludge Dewatering Machine QXDL-301

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP