- 1 A Solid-Liquid Separation Solution for the New Age of Environmental Protection

- 2 The Challenge: The Burden of Sludge in an Era of Environmentalism

- 3 Why the Screw Press is the Future of Sludge Dewatering

- 4 Maximizing Value within Wastewater Treatment Systems

- 5 The New Role of Solid-Liquid Separation in Sustainability and Resource Recovery

- 6 Seizing the Future with an Efficient Solution

A Solid-Liquid Separation Solution for the New Age of Environmental Protection

The Challenge: The Burden of Sludge in an Era of Environmentalism

The rapid pace of urbanization and industrialization has led to a significant increase in the volume of sludge and wastewater, placing a heavy burden on our environment. Traditional dewatering methods, such as plate and frame filter presses, often fall short due to their low efficiency, high energy consumption, and complex maintenance.

This is where the screw press dewatering machine comes in. It is a state-of-the-art solution that addresses these challenges head-on, ushering in a new era for sludge treatment.

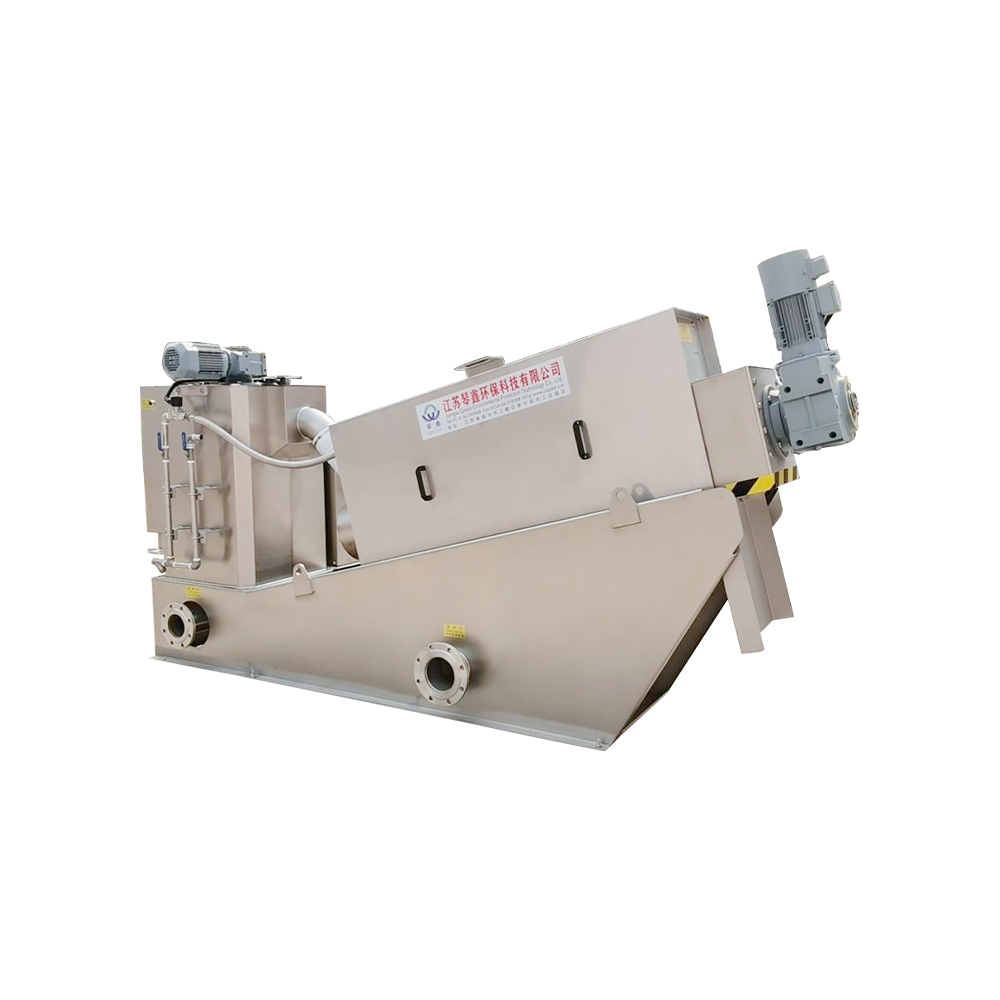

Eco-friendly Solid-Liquid Separation Spiral Screw Sludge Dewatering Machine QXDL-301

Why the Screw Press is the Future of Sludge Dewatering

The screw press dewatering machine is considered the future of sludge dewatering because it solves the major problems associated with traditional equipment, delivering significant improvements in efficiency, energy use, and maintenance.

The Revolutionary Principle: Self-Cleaning and Continuous Dewatering

Unlike traditional devices that use external pressure to squeeze water out of sludge, the screw press uses a different approach. Its core consists of a slowly rotating screw shaft enclosed by a series of fixed and moving rings. As sludge is fed in, the shaft's rotation pushes the sludge forward. The pitch of the screw gradually decreases, and a backpressure plate at the end of the machine increases the pressure, effectively squeezing the water out.

The most innovative feature is its self-cleaning mechanism. The slow rotation of the screw shaft continuously moves the floating rings against the fixed rings. This constant motion prevents clogging, a common problem with conventional filter presses. This design allows the machine to operate continuously for 24 hours without interruption or manual intervention.

Key Advantages: A Parameter Comparison

Here is a direct comparison of the key advantages of a screw press dewatering machine over a traditional plate and frame filter press:

| Parameter | Screw Press Dewatering Machine | Traditional Plate and Frame Press |

|---|---|---|

| Dewatering Method | Continuous, fully automatic | Intermittent |

| Clogging Issues | Self-cleaning design, almost no clogging | Filter cloths are prone to clogging, requiring manual cleaning |

| Energy Consumption | Low, approximately 10% of a plate press with the same capacity | High, requires high-power pumps and air compressors |

| Maintenance | Low, no filter cloths to replace, simple maintenance | High, filter cloths require frequent replacement and cleaning |

| Footprint | Small, compact structure | Large, requires extra space for filter cloth washing and storage |

| Noise Level | Low, slow-speed rotation, minimal vibration | High, noisy pumps and air compressors |

Maximizing Value within Wastewater Treatment Systems

The screw press dewatering machine is more than just a single piece of equipment; its true power lies in its ability to act as a crucial component within a larger wastewater treatment equipment system.

A Holistic View: Synergy from Start to Finish

A complete wastewater treatment system typically includes pre-treatment, biological treatment, and sludge treatment. The screw press plays a vital role in the final sludge treatment phase. Its efficiency directly impacts the entire system's operational costs and environmental performance.

For instance, if pre-treatment generates a large volume of sludge with high water content, ineffective dewatering will lead to several cascading problems:

- High Transportation Costs: Sludge with high moisture content is heavy and bulky, increasing transportation expenses.

- Difficult Downstream Processing: Subsequent processes like incineration, composting, or landfilling have strict moisture content requirements. High water content makes these processes more difficult and energy-intensive.

- Risk of Secondary Pollution: Inadequately dewatered sludge can produce leachate during transport or storage, leading to secondary pollution.

By effectively reducing the sludge's moisture content, the screw press ensures that these downstream processes are more efficient and cost-effective, thus maximizing the value of the entire wastewater treatment equipment system.

The New Role of Solid-Liquid Separation in Sustainability and Resource Recovery

Today's solid-liquid separation technology is transforming from a simple waste disposal method into a key driver of the circular economy. The screw press turns sludge from an environmental burden into a potential resource.

Policy-Driven Compliance

Environmental regulations are becoming increasingly stringent, particularly regarding sludge treatment and disposal. Many governments require sludge moisture content to be below a certain threshold before it can be landfilled or incinerated.

Traditional solid-liquid separation technology often struggles to meet these strict standards, exposing businesses to fines and operational risks. The screw press, with its superior dewatering capabilities, helps companies easily comply with these regulations, mitigating risks and ensuring sustainable operations.

Resource Recovery: Turning Sludge into Value

Efficient solid-liquid separation is the foundation of sludge resource recovery. After being processed by a screw press, sludge's moisture content is significantly reduced, opening up new avenues for resource utilization:

| Resource Recovery Path | Processing Requirements | Contribution of the Screw Press |

|---|---|---|

| Incineration for Power | High heating value; moisture content is a critical factor | Significantly reduces moisture content, cutting fuel costs and improving combustion efficiency |

| Construction Materials | Requires low moisture content for shaping and drying | Produces a drier sludge cake that is easier to mix with other materials to make bricks or cement |

| Biological Composting | Lower moisture content improves physical properties and aids fermentation | Reduces transport volume and land requirements for composting, accelerating the fermentation process |

As the table shows, the screw press goes beyond simple dewatering. Through efficient solid-liquid separation, it directly influences the economic value and potential uses of sludge, acting as a bridge between waste and resources, and between environmental protection and profitability.

Seizing the Future with an Efficient Solution

In summary, the screw press dewatering machine offers a comprehensive solution that combines technical innovation, economic efficiency, and environmental benefits. It addresses the fundamental challenges of traditional sludge treatment, offering a path to greater efficiency and sustainability.

Core Value: The Winning Solution

- Extremely Low Operating Costs: The screw press's low-speed operation and self-cleaning design result in minimal power and water consumption, drastically reducing a company's daily sludge treatment expenses.

- Full Automatic, Continuous Operation: The machine operates continuously for 24 hours without the need for constant supervision, saving labor costs. Its self-cleaning function prevents clogging, ensuring stable, long-term performance.

- Broad Applicability: Whether it's municipal primary sludge or industrial sludge from food processing, chemical, or other industries, the screw press dewatering machine delivers consistent, high-performance dewatering.

Outlook for the Future: Dual Upgrades in Technology and Service

With the advancement of IoT, big data, and other technologies, future screw press dewatering machines will become even smarter. Through remote monitoring, fault early warning, and data analysis, equipment will be able to achieve more precise operational control and more efficient maintenance management, further enhancing its position in the field of solid-liquid separation.

This is precisely the philosophy upheld by companies like Yangzhou Qinxin Environmental Protection Technology Co., Ltd. As an enterprise that combines industry and trade, we are committed to the research, development, and sales of environmental protection equipment. With years of practical experience and R&D expertise, we provide efficient and reliable stacked screw sludge dewatering machines, along with comprehensive sludge treatment solutions for various sectors. We understand that businesses need more than just equipment—they need a strategy to face future challenges.

Choosing a screw press from Yangzhou Qinxin Environmental Protection Technology Co., Ltd. means you are choosing a future-proof solution that will help you reduce costs, improve efficiency, comply with environmental regulations, and unlock the resource potential of your sludge. We look forward to partnering with you to create a new chapter in environmental protection.

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP