The Growing Importance of Efficient Solid-Liquid Separation

As industries face increasing pressure to optimize waste management and resource recovery, solid-liquid separator technology has emerged as a critical solution. These systems are transforming how businesses handle slurry, wastewater, and industrial byproducts.

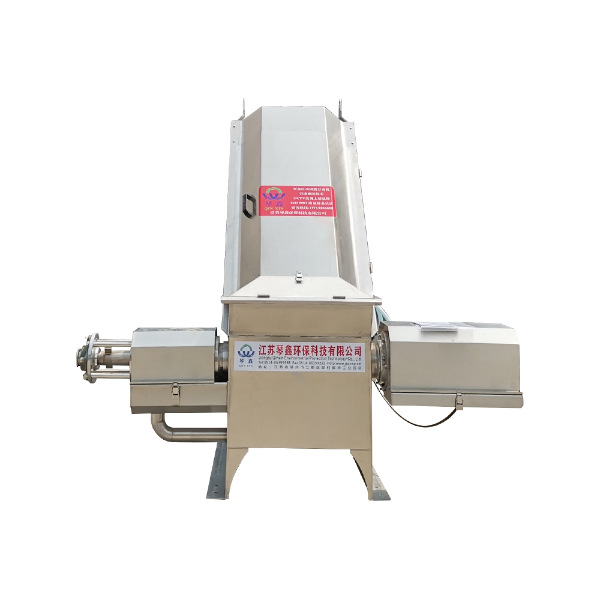

Expression Press Solid-Liquid Separation Sludge Separator QX-60T

Key Applications of Solid-Liquid Separation Systems

1. Industrial wastewater treatment with decanter centrifuges

Decanter centrifuges have become the workhorse of industrial wastewater treatment, offering superior separation efficiency compared to traditional methods. These systems can handle flows ranging from 5 to 150 m³/h with solids recovery rates exceeding 95%.

When comparing decanter centrifuges to other separation methods:

| Method | Solids Recovery | Energy Use | Footprint |

|---|---|---|---|

| Decanter Centrifuge | 95-99% | High | Compact |

| Filter Press | 90-95% | Medium | Large |

| Settling Pond | 70-85% | Low | Very Large |

2. Sludge dewatering equipment for municipal plants

Municipal wastewater treatment facilities are increasingly adopting advanced sludge dewatering equipment to reduce disposal costs and improve processing efficiency. Modern systems can reduce sludge volume by up to 80%, significantly cutting transportation and landfill expenses.

Emerging Technologies in Phase Separation

3. High-speed centrifugation for food processing

The food industry benefits tremendously from specialized high-speed centrifugation systems that maintain product quality while achieving separation. Dairy processing, for instance, requires precise fat separation at speeds up to 10,000 RPM without damaging delicate proteins.

4. Compact separator systems for small-scale operations

Small businesses and rural operations now have access to compact separator systems that deliver industrial-grade performance in modest packages. These units typically process 1-5 tons per hour while occupying less than 10 square meters of floor space.

Optimizing Separation Processes

5. Automated control systems for separation equipment

The integration of automated control systems has dramatically improved separation consistency and reduced labor requirements. Modern PLC-controlled units can adjust parameters in real-time based on feed composition sensors, ensuring optimal performance across varying conditions.

Future Trends in Separation Technology

As environmental regulations tighten globally, the demand for more efficient solid-liquid separator solutions will continue growing. Emerging technologies like membrane-enhanced separation and AI-optimized processes promise to deliver even better performance in the coming years.

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP