Solid-liquid separation is a fundamental process across countless industries, from purifying drinking water to manufacturing pharmaceuticals. It's the critical step that transforms a mixed suspension into distinct solid and liquid phases. Understanding how these systems work and which type is best for a given application can significantly impact efficiency, product quality, and cost.

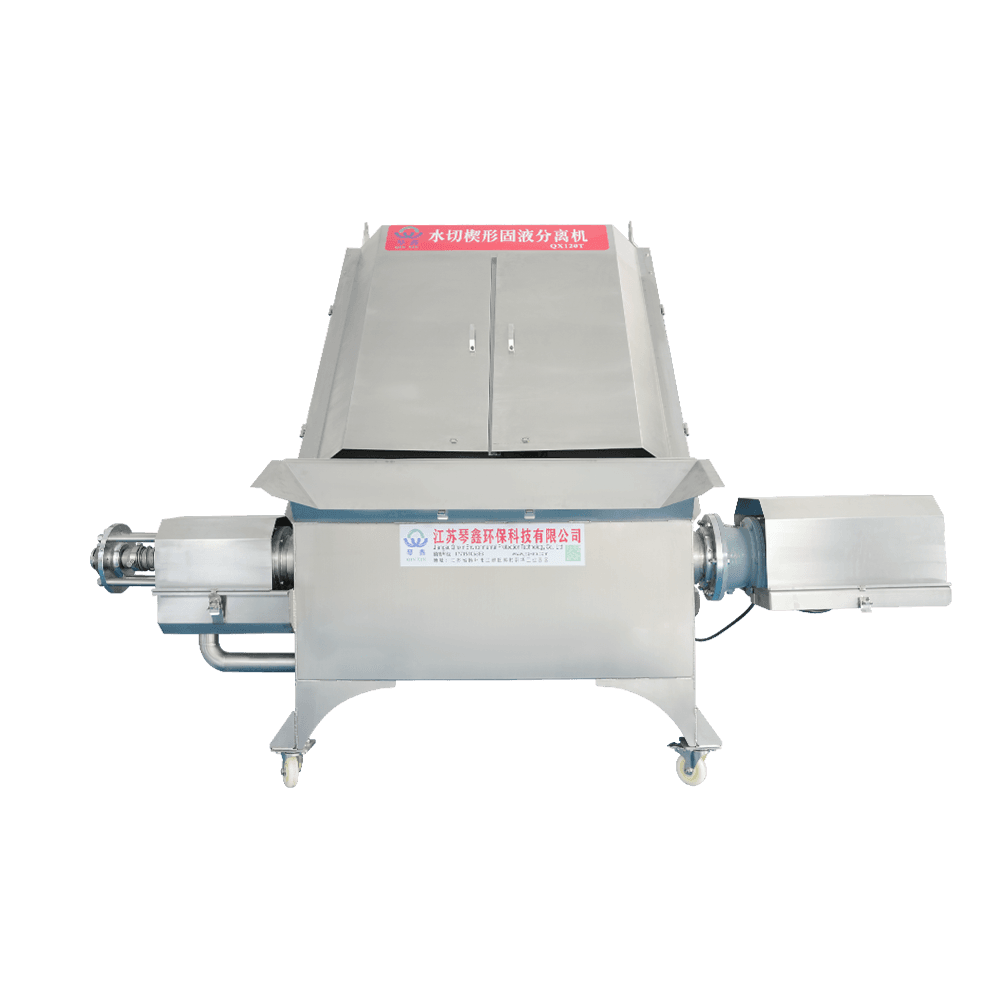

Waste Water Treatment Inclined Screen Solid-Liquid Separator QX-120T

How Solid-Liquid Separators Work

Solid-liquid separators operate on various physical separation mechanisms to achieve their goal. These methods leverage inherent differences between solids and liquids to encourage their segregation:

Gravity Settling: The simplest method, where denser solid particles settle out of a liquid due to gravity.

Centrifugal Force: Spinning a mixture at high speeds creates a strong outward force, rapidly separating components based on density.

Filtration: Passing a mixture through a porous medium that retains solid particles while allowing the liquid to pass through.

Pressing/Squeezing: Applying mechanical pressure to compress a solid-liquid mixture, forcing the liquid out.

The effectiveness of a separator is typically measured by key parameters such as:

Separation Efficiency: How completely the solids are removed from the liquid, or vice versa.

Processing Capacity: The volume of material the separator can handle per unit of time.

Energy Consumption: The power required to operate the equipment.

Common Types of Solid-Liquid Separators

The market offers a diverse range of solid-liquid separators, each designed for specific applications and material characteristics.

Centrifugal Separators

Working Principle: These separators utilize centrifugal force to accelerate the solid-liquid separation process. The mixture is introduced into a rapidly rotating bowl or drum, which throws denser solids outwards, accumulating them against the wall, while the lighter liquid forms an inner layer.

Applications: Widely used in various sectors, including chemical processing , food processing (e.g., milk clarification, oil purification), and pharmaceutical manufacturing (e.g., cell harvesting, product recovery).

Belt Press Separators

Working Principle: Belt press separators dewater materials by passing them between two tensioned porous filter belts. As the belts converge, they apply increasing pressure , squeezing the liquid out of the solid material.

Applications: Primarily used for wastewater treatment and sludge dewatering in municipal and industrial settings due to their continuous operation and ability to handle large volumes of dilute slurries.

Screw Press Separators

Working Principle: These machines use a rotating screw inside a cylindrical screen or casing. As the screw rotates, it continuously conveys and compresses the solid-liquid mixture, progressively increasing pressure and forcing the liquid through the screen, while the dewatered solids are discharged.

Applications: Common in agricultural waste processing (e.g., manure separation), food processing (e.g., fruit and vegetable pressing), and other industries where moderate dewatering is required.

Filter Presses

Working Principle: Filter presses operate on the principle of high-pressure filtration . A series of plates, each covered with a filter cloth, are pressed together to form chambers. The solid-liquid slurry is pumped into these chambers under high pressure, forcing the liquid through the filter cloth while trapping the solids (filter cake) within the chambers.

Applications: Frequently employed in the mining industry (e.g., tailing dewatering, mineral concentrate filtration) and metallurgical industries for their ability to achieve very dry filter cakes and high separation efficiency.

Key Application Areas for Solid-Liquid Separators

Solid-liquid separators are indispensable tools across a vast array of industries, contributing to product quality, waste reduction, and process efficiency.

Wastewater Treatment

In wastewater treatment , these separators are crucial for sludge dewatering to reduce disposal volumes and costs, and for industrial wastewater treatment to remove pollutants before discharge or further treatment.

Food Industry

The food industry relies heavily on solid-liquid separation for processes like fruit juice clarification (removing pulp), dairy product processing (e.g., separating cream from milk), and general ingredient preparation.

Chemical & Pharmaceutical

In chemical and pharmaceutical manufacturing , separators are vital for crystallization separation (isolating crystals from mother liquor) and catalyst recovery (recovering valuable catalysts from reaction mixtures).

Mining Industry

The mining industry uses these systems extensively for tailings treatment (dewatering waste slurry) and mineral concentration (separating valuable minerals from gangue).

How to Choose the Right Solid-Liquid Separator

Selecting the appropriate solid-liquid separator is a critical decision that impacts operational efficiency and cost. Several factors must be carefully considered:

Material Characteristics: The particle size and distribution of the solids, the viscosity of the liquid, the corrosiveness of the mixture, and the temperature all play a significant role.

Processing Capacity: The required throughput or volume of material to be processed per hour or day.

Automation Requirements: The desired level of automation, from manual operation to fully automated systems with integrated controls.

For example, industries dealing with very fine particles might lean towards centrifugal separators or filter presses, while those handling large volumes of less demanding slurries might opt for belt presses.

Maintenance and Optimization

Proper maintenance is essential for ensuring the longevity and optimal performance of any solid-liquid separator.

Common Faults and Solutions: Regular inspection of moving parts, filter media, and seals can prevent issues like blockages, leaks, or reduced efficiency. Addressing wear and tear promptly is key.

Improving Separation Efficiency and Reducing Energy Consumption: This can be achieved through regular cleaning of filter media, optimizing operational parameters like feed rate and pressure, and ensuring components are in good working order. Preventive maintenance schedules can significantly extend equipment life and maintain peak performance.

By understanding the principles, types, applications, and selection criteria for solid-liquid separators, industries can make informed decisions to optimize their processes and achieve desired separation outcomes.

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP