Introduction to Screw Press Sludge Dewatering

What is Screw Press Sludge Dewatering?

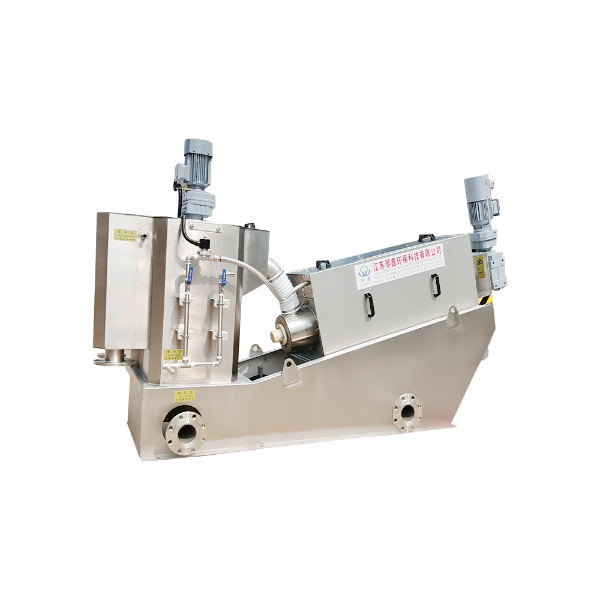

A screw press sludge dewatering machine is a mechanical device used to remove excess water from sludge, primarily in wastewater treatment plants. The technology uses a screw-like auger to compress the sludge, forcing out moisture. This process helps in reducing the volume of waste, making it easier and more cost-effective to handle, transport, and dispose of. It's widely used in both municipal and industrial applications to optimize waste management.

Importance of Sludge Dewatering in Industrial Facilities

Effective sludge management is crucial for industries like food processing, chemical manufacturing, and wastewater treatment. Sludge contains contaminants and excess moisture, which, if left untreated, can lead to environmental pollution and increased disposal costs. A screw press sludge removal machine helps to efficiently reduce the volume and weight of the sludge, ensuring better management and disposal options. Additionally, it helps improve the overall performance of the treatment plant.

- Reduces sludge volume for easier handling

- Decreases disposal costs

- Improves environmental compliance

Benefits of Screw Press Sludge Dewatering Machines

Enhanced Sludge Separation and Efficiency

The screw press technology offers several advantages over traditional dewatering methods. One of the key benefits is its ability to separate water from sludge more effectively. The pressing mechanism works efficiently under varying conditions, allowing consistent results even with different sludge types. This ensures a high quality of dewatered sludge with reduced moisture content.

- Reduces moisture content in sludge

- Achieves higher dewatering efficiency

- Handles varying sludge compositions

Energy Efficiency and Cost Reduction

Unlike other dewatering systems like centrifuges, which require a significant amount of energy, screw press systems are known for their energy efficiency. The mechanical design ensures minimal energy consumption while still providing effective sludge dewatering. This results in lower operating costs for industrial facilities and helps in achieving long-term financial savings.

- Consumes less energy than centrifuges

- Lower operational and maintenance costs

- Longer machine lifespan

Food Grade Energy-Saving Press Dewatering Machine Spiral Screw Sludge Dewatering Machine QXDL-251

How Screw Press Sludge Dewatering Machines Work

Working Principle of Screw Press

The screw press operates by using an auger or screw that gradually pushes the sludge through a wedge-shaped channel. As the sludge moves through the press, the auger exerts pressure, squeezing the liquid out while retaining the solid material. This process occurs in several stages: from the inlet to the dewatering zone, and finally to the discharge of the dewatered sludge.

- Sludge enters the machine and is progressively compressed

- Excess water is forced out through perforations in the drum

- Dehydrated sludge is collected at the end

Key Features of a Screw Press Sludge Dewatering Machine

Key features that make screw press machines highly efficient include automatic control systems, compact design, and the ability to handle large volumes of sludge. Some models also feature adjustable screw speeds and customizable filter options, allowing for optimized dewatering based on the type of sludge being treated.

- Automatic control systems for ease of operation

- Compact design for space-saving installation

- Customizable features based on sludge type

Comparing Screw Press with Other Dewatering Methods

Screw Press vs. Centrifuge

Both screw presses and centrifuges are widely used for sludge dewatering. However, screw presses offer some distinct advantages over centrifuges, including lower energy consumption, simpler maintenance, and better handling of varying sludge types. Centrifuges, while faster, tend to require more frequent maintenance and higher energy inputs.

| Feature | Screw Press | Centrifuge |

| Energy Consumption | Low | High |

| Maintenance | Low | High |

| Handling of Sludge | Varied types | Less flexible |

Screw Press vs. Belt Filter Press

The belt filter press is another common dewatering method. While it shares similarities with the screw press, the screw press typically has a more compact design and is easier to install in tight spaces. Moreover, screw presses tend to handle high solids content better than belt presses, which might clog with thicker sludge.

| Feature | Screw Press | Belt Filter Press |

| Design | Compact | Bulky |

| Sludge Handling | Handles high solids | Prone to clogging |

Applications of Screw Press Sludge Dewatering Machines

Use in Municipal Wastewater Treatment Plants

In municipal wastewater treatment, screw presses help to manage large volumes of sewage sludge. These machines reduce the volume of waste, which lowers the costs of transportation and disposal. Additionally, the dewatered sludge can be repurposed for various uses, including composting or energy generation.

- Optimizes municipal sludge treatment

- Reduces transportation and disposal costs

- Facilitates composting and energy generation

Use in Industrial Sludge Management

Industrial facilities, such as food processing plants and chemical manufacturers, generate large amounts of sludge that must be treated. A screw press offers an ideal solution for these industries, as it effectively handles thick and high-solid-content sludge, reducing operational costs and ensuring compliance with environmental regulations.

- Handles high-solid sludge from industrial processes

- Improves compliance with environmental standards

- Reduces overall waste management costs

FAQ

What are the advantages of using a screw press for sludge dewatering?

A screw press offers multiple benefits, such as energy efficiency, lower maintenance, and handling a variety of sludge types. Compared to other dewatering methods like centrifuges or belt presses, it consumes less energy and requires fewer resources, making it more cost-effective in the long run.

How does screw press dewatering compare to other methods like centrifugation?

While centrifuges are fast and effective for some applications, screw presses excel in handling varied sludge types, are more energy-efficient, and have lower operational costs. Centrifuges typically require more maintenance and higher energy inputs, whereas screw presses provide a more sustainable solution for sludge management.

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP