- 1 What is a Screw Dewatering Machine? Understanding the Core Technology

- 2

- 3 How Does a Screw Press Dewatering Machine Work? A Step-by-Step Breakdown

- 4 Key Applications of Screw Dewatering Machines Across Industries

- 5 Advantages and Disadvantages of Screw Press Dewatering Technology

- 6 Choosing the Right Screw Dewatering Machine: A Buyer's Considerations

- 7 Essential Maintenance Guide for Industrial Screw Press Dewatering Machines

- 8 FAQ

In the world of industrial processing and environmental management, efficiently separating solids from liquids is a critical and often costly operation. Among the various technologies available, the screw dewatering machine, also known as a screw press, stands out for its reliability, simplicity, and effectiveness. This comprehensive guide delves deep into the workings, applications, and benefits of this versatile equipment, providing you with the knowledge needed to evaluate its suitability for your operations. Whether you're in wastewater treatment, food processing, or any industry dealing with slurry or sludge, understanding this technology is key to optimizing your processes.

What is a Screw Dewatering Machine? Understanding the Core Technology

A screw dewatering machine is a mechanical separation device that uses a rotating screw (auger) inside a cylindrical screen to continuously convey and compress solid materials. As the slurry is fed into the machine, the screw transports it while the volume gradually decreases, applying increasing pressure to squeeze out the liquid. The liquid (filtrate) passes through the screen, while the dewatered solids are discharged from the end. This continuous process makes it highly efficient for handling large volumes of waste or product streams.

- Continuous Operation: Unlike batch processes, screw presses work non-stop, ensuring consistent throughput.

- Adaptability: They can be tailored with different screen sizes, screw speeds, and compression ratios to handle a wide range of materials.

- Low Energy Consumption: Compared to other dewatering methods like centrifuges, screw presses typically require less power to operate.

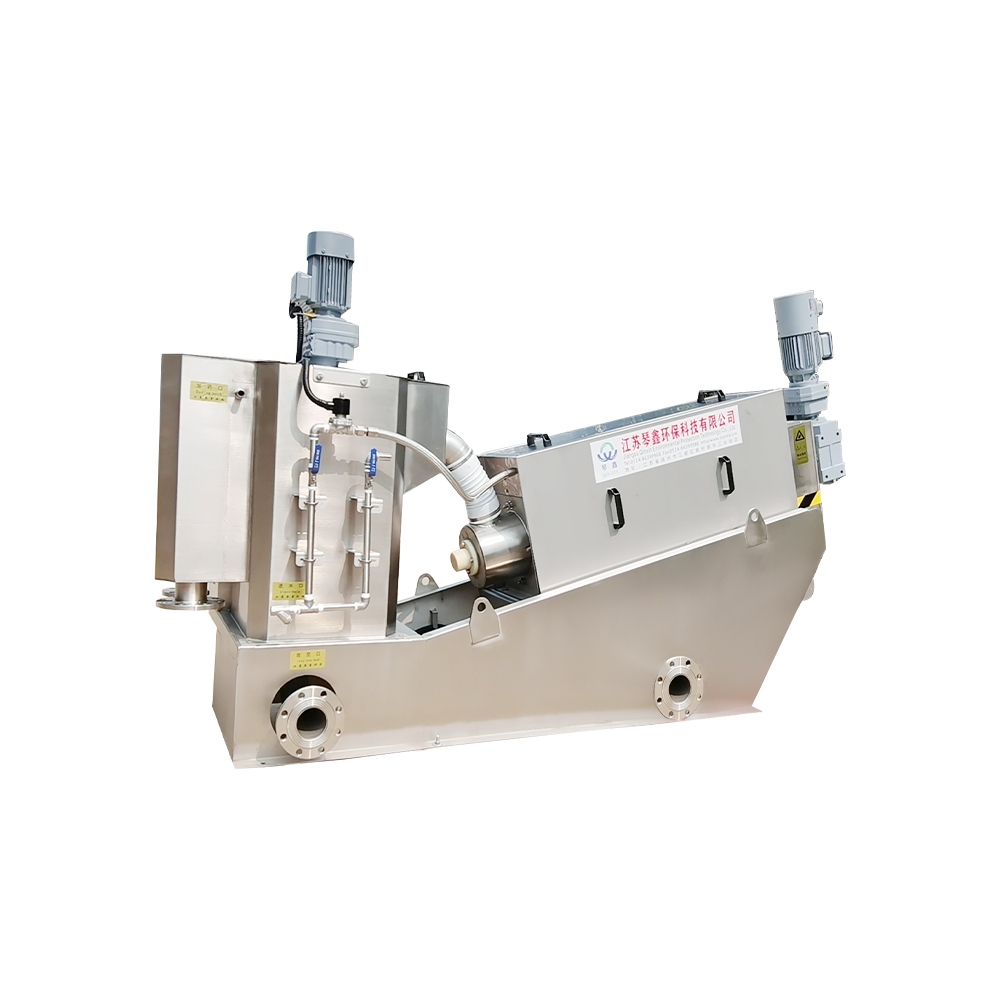

Food Grade Energy-Saving Press Dewatering Machine Spiral Screw Sludge Dewatering Machine QXDL-251

How Does a Screw Press Dewatering Machine Work? A Step-by-Step Breakdown

Understanding how does a screw press dewatering machine work is crucial to appreciating its efficiency. The process is elegantly simple yet highly effective, involving several distinct stages within a single, compact unit.

- Stage 1: Feeding: The slurry is pumped into the inlet chamber of the press.

- Stage 2: Gravity Drainage: As the material is conveyed by the slow-turning screw, free water begins to drain through the screen by gravity.

- Stage 3: Progressive Compression: The pitch of the screw flights decreases, and the diameter of the shaft often increases, creating a gradually tighter space. This applies mechanical pressure, forcing more liquid out.

- Stage 4: Counter-Pressure Discharge: At the discharge end, a cone or plate creates a back-pressure, ensuring the solids are compressed to the desired dryness before being ejected.

Key Components of a Screw Dewatering System

The effectiveness of the system relies on its core components, each playing a vital role in the separation process.

- The Screw (Auger): The heart of the machine, responsible for conveying and compressing the material.

- Screen Cylinder: A perforated or wedge-wire screen that allows liquid to pass while retaining solids.

- Drive System: Typically an electric motor with a gear reducer, controlling the screw's rotational speed.

- Counter-Pressure Mechanism: An adjustable weight, spring, or pneumatic system at the discharge end to control the final solids dryness.

Key Applications of Screw Dewatering Machines Across Industries

The versatility of the screw dewatering machine makes it suitable for a multitude of applications. Its ability to handle various organic and inorganic sludges is a primary reason for its widespread adoption.

Applications of Screw Dewatering Machine in Wastewater Treatment

This is one of the most common uses. The applications of screw dewatering machine in wastewater treatment are extensive, focusing on reducing the volume of sludge for cost-effective disposal or further processing.

- Dewatering of activated sludge from biological treatment processes.

- Thickening and dewatering of primary sludge.

- Handling of mixed sludge (primary and secondary combined).

Screw Dewatering Machine for Sludge Treatment in Municipal Plants

Specifically, when we talk about a screw dewatering machine for sludge treatment in a municipal context, the goal is to transform liquid sludge into a cake with a dry solids content of 15-30%, significantly reducing transportation and landfill costs.

Food and Agricultural Waste Processing

Beyond wastewater, these machines excel in the food and agricultural sectors.

- Dejuicing fruit and vegetable pulps (e.g., apples for cider, tomatoes for sauce).

- Recovering protein from slaughterhouse waste.

- Dewatering manure for easier handling and odor reduction.

Advantages and Disadvantages of Screw Press Dewatering Technology

When selecting dewatering equipment, a balanced view is essential. Here, we explore the key advantages and disadvantages of screw press dewatering to help you make an informed decision.

- Advantages: Low energy consumption, quiet operation, minimal vibration, simple automation, and relatively low maintenance requirements.

- Disadvantages: May require pre-conditioning of sludge with polymers, potentially lower dryness compared to a centrifuge for some materials, and the screen can be prone to clogging if not properly maintained.

Evaluating the Pros and Cons for Your Project

The following table provides a quick comparison to contextualize the advantages and disadvantages of screw press dewatering against common alternatives.

| Feature | Screw Press | Centrifuge | Belt Filter Press |

| Energy Use | Low | High | Medium |

| Noise Level | Low | High | Medium |

| Dryness Achieved | Medium-High | High | Medium |

| Maintenance Complexity | Low-Medium | High | Medium |

| Footprint | Compact | Compact | Large |

Choosing the Right Screw Dewatering Machine: A Buyer's Considerations

Selecting the appropriate screw dewatering machine requires a careful analysis of your specific needs. A one-size-fits-all approach does not apply.

- Feed Material Characteristics: Analyze the particle size, abrasiveness, viscosity, and expected solid concentration of your slurry.

- Required Capacity: Determine the hourly or daily volume of material that needs processing.

- Desired End Result: Define the target dryness of the solid cake and the clarity required for the filtrate.

- Site Conditions: Consider available space, power supply, and water source for cleaning.

Essential Maintenance Guide for Industrial Screw Press Dewatering Machines

To ensure longevity and consistent performance, a proactive approach to maintenance is non-negotiable. This maintenance guide for industrial screw press dewatering machines outlines the key routines.

Regular maintenance prevents unexpected downtime and costly repairs. The focus should be on the components subject to the most wear and tear.

- Daily: Inspect for unusual noises or vibrations, check oil levels in the gearbox, and ensure the spray nozzles for screen cleaning are not clogged.

- Weekly/Monthly: Check the wear on the screw flights and the screen for any signs of damage or blockage. Lubricate bearings as per the manufacturer's schedule.

- Annually: Consider a comprehensive inspection, which may involve replacing worn seals, bearings, and other critical components.

FAQ

What is the typical dry solids content achieved by a screw dewatering machine?

The final dry solids content varies significantly based on the feed material's characteristics and whether chemical conditioners are used. For municipal biological sludges, a well-operated screw dewatering machine can typically achieve between 15% and 25% dry solids. For more fibrous materials like food waste or primary sludge, this can often exceed 30%.

Do I always need to use polymers with a screw press?

Not always, but it is very common, especially for sludges with fine particles that don't separate easily. Polymers (flocculants) bind the fine solids together into larger flocs, making it easier for the press to capture them and release water. Some coarse, fibrous materials may dewater effectively without polymers, but a trial is usually recommended to be sure.

How does a screw press differ from a centrifuge for sludge dewatering?

While both are effective, the core difference lies in the separation force. A screw press dewatering machine uses gradual mechanical pressure, while a centrifuge uses high centrifugal force. Screw presses are generally more energy-efficient, quieter, and have lower maintenance, but centrifuges can often achieve a higher dryness and have a smaller footprint for a given capacity. The choice depends on the specific trade-offs important to your operation.

What are the most common operational issues with a screw press?

The most common issues include screen blinding (clogging), which can be mitigated by proper cleaning and polymer dosing; wear of the screw and screen due to abrasive materials; and over-tightening the back-pressure, which can stall the drive. Following the maintenance guide for industrial screw press dewatering machines provided by the manufacturer is the best defense against these problems.

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP