Optimizing Chemical Dosing Efficiency in Water Treatment Plants

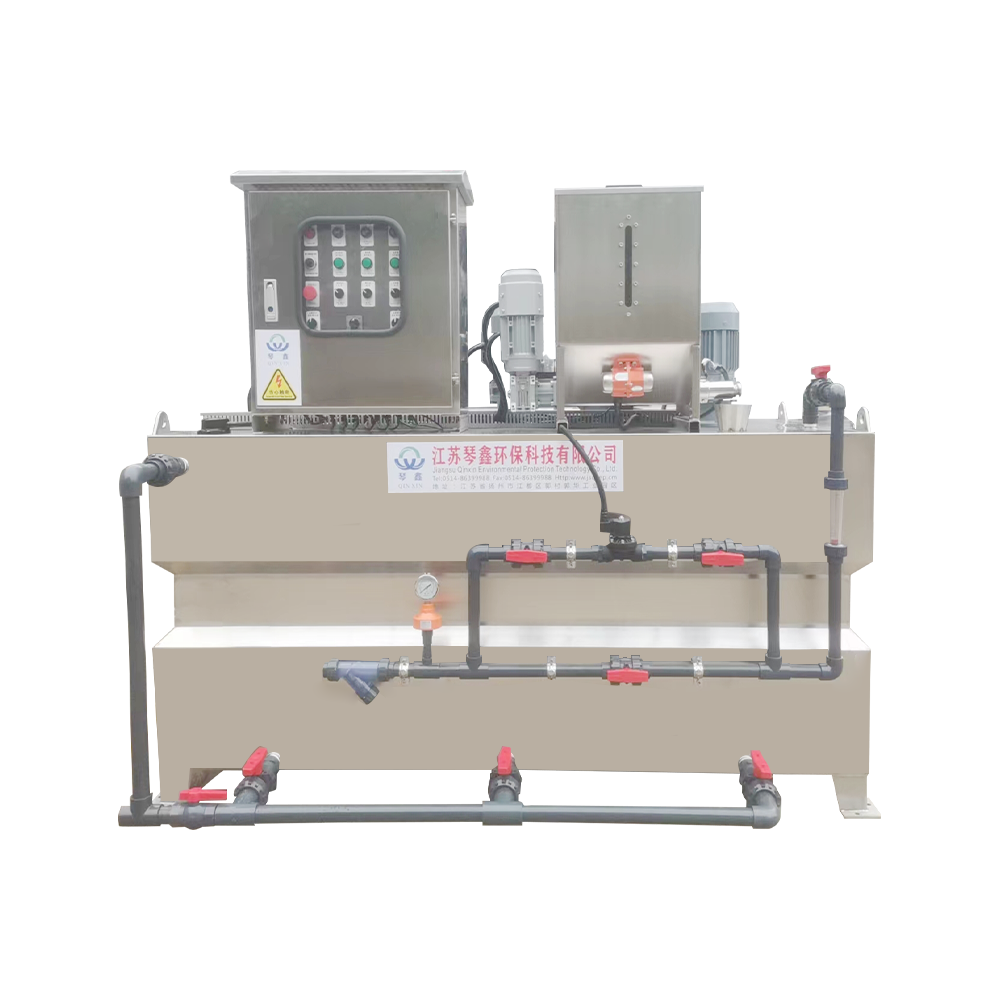

The PMA-integrated frequency-converting dosing device is a cutting-edge solution designed to enhance precision, efficiency, and reliability in water treatment applications. By combining PMA (Pulse Modulation Analysis) technology with frequency conversion control, this dosing system ensures accurate chemical delivery while minimizing energy consumption and operational costs.

Water treatment plants require consistent and precise chemical dosing to maintain water quality, prevent scaling/corrosion, and comply with environmental regulations. Traditional dosing pumps often struggle with flow variations, leading to overdosing or underdosing. The PMA-integrated frequency-converting dosing device dynamically adjusts pump speed based on real-time demand, ensuring optimal chemical injection without waste.

Key Benefits for Water Treatment Applications:

Precision Dosing: Automatic flow adjustment based on system feedback.

Energy Efficiency: Frequency conversion reduces power consumption by up to 40%.

Reduced Maintenance: PMA technology minimizes wear and tear on pump components.

Smart Integration: Compatible with SCADA and IoT-based monitoring systems.

How to Calibrate PMA-Integrated Frequency-Converting Dosing Pump

Proper calibration is essential to maintain dosing accuracy in water treatment systems. Follow these steps to ensure optimal performance:

Step 1: Initial Setup & System Check

Verify that the pump is correctly installed and all connections are secure.

Ensure the control panel displays the correct parameters (flow rate, pressure, frequency).

Step 2: Enter Calibration Mode

Access the pump’s control interface and select "Calibration Mode."

Input the desired dosing rate (e.g., liters/hour or gallons/day).

Step 3: Flow Verification & Adjustment

Use a calibrated flow meter to measure actual output.

Adjust the frequency converter to match the target flow rate.

Repeat until the deviation is within ±1% accuracy.

Step 4: Save Settings & Perform Test Run

Confirm calibration data and save to the system memory.

Conduct a 24-hour test run to ensure stability under real-world conditions.

Pro Tip: Schedule recalibration every 6 months or after major system changes to maintain peak efficiency.

Industrial Chemical Dosing System with PMA and Frequency Conversion

Beyond water treatment, PMA-integrated frequency-converting dosing systems are widely used in industrial chemical processing, including:

1. Oil & Gas Industry

Precustion injection of corrosion inhibitors and scale preventers.

Adaptive flow control for varying pipeline pressures.

2. Food & Beverage Production

Accurate pH adjustment in CIP (Clean-in-Place) systems.

Consistent additive dosing for flavor and preservation.

3. Pharmaceutical Manufacturing

High-precision reagent delivery in batch processing.

Compliance with GMP (Good Manufacturing Practices) standards.

Why Choose PMA + Frequency Conversion?

Dynamic Response: Automatically adapts to process fluctuations.

Lower Operational Costs: Reduces chemical waste and energy use.

Longer Equipment Lifespan: Minimizes mechanical stress on pumps.

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP