- 1 Understanding the Role of PAM Integrated Dosing Device in Wastewater Treatment

- 2 Key Considerations for PAM dosing system installation requirements

- 3 Optimizing Performance with automated PAM dosing equipment benefits

- 4 Essential PAM dosing system maintenance guide Practices

- 5 Exploring cost-effective PAM dosing solutions for Various Applications

Understanding the Role of PAM Integrated Dosing Device in Wastewater Treatment

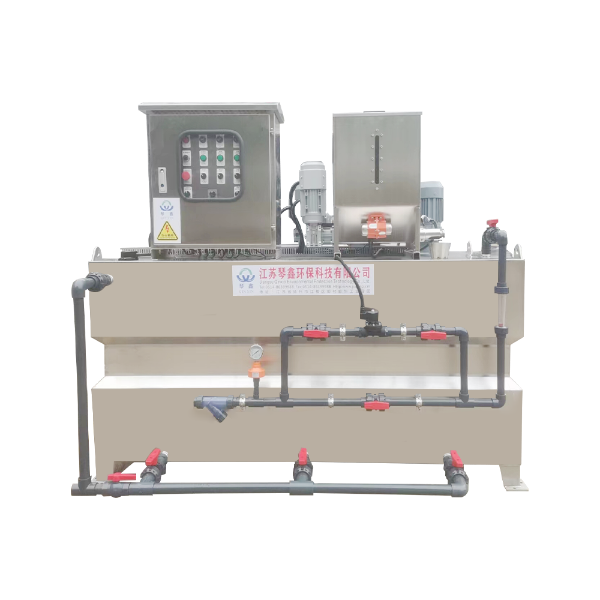

Polyacrylamide (PAM) integrated dosing devices have become essential components in modern wastewater treatment systems. These specialized devices are designed to accurately meter and deliver polyacrylamide solutions, which play a crucial role in flocculation processes. The PAM integrated dosing device in wastewater treatment offers numerous advantages over traditional dosing methods, including improved accuracy, reduced chemical waste, and enhanced process control.

How PAM Dosing Systems Improve Treatment Efficiency

The integration of PAM dosing systems into wastewater treatment plants has revolutionized the flocculation process. These devices typically consist of several key components:

- Precision metering pumps for accurate chemical delivery

- Advanced mixing chambers for optimal polymer activation

- Automated control systems for consistent performance

- Real-time monitoring sensors for process adjustment

- Safety features to prevent overdosing or system failures

Comparison Between Traditional and Integrated Dosing Methods

When evaluating PAM dosing system installation requirements, it's important to understand how integrated systems differ from conventional approaches:

| Feature | Traditional Dosing | Integrated Dosing |

|---|---|---|

| Accuracy | ±10-15% | ±1-2% |

| Chemical Waste | High (15-20%) | Low (2-5%) |

| Automation Level | Manual adjustments | Fully automated |

| Footprint | Large | Compact |

Key Considerations for PAM dosing system installation requirements

Proper installation of a PAM integrated dosing device is critical for optimal performance and longevity. The installation process involves several technical considerations that must be addressed to ensure the system operates at peak efficiency.

Site Preparation and Space Requirements

Before installing a PAM dosing system for industrial applications, careful evaluation of the installation site must be conducted. The space requirements will vary depending on the system's capacity and configuration, but generally include:

- Adequate clearance for maintenance access

- Proper ventilation for chemical storage areas

- Level foundation to prevent vibration and misalignment

- Proximity to water supply and drainage points

- Access to electrical connections with proper voltage

Technical Specifications and Compatibility

The automated PAM dosing equipment benefits can only be fully realized when the system is properly matched to the application requirements. Key technical specifications to consider include:

- Flow rate capacity matching treatment needs

- Pressure rating compatible with existing systems

- Materials of construction suitable for PAM solutions

- Control system integration capabilities

- Environmental conditions (temperature, humidity)

Optimizing Performance with automated PAM dosing equipment benefits

Automation brings numerous advantages to PAM dosing operations, transforming what was once a labor-intensive process into a precise, efficient, and reliable system.

Precision Dosing and Consistency

Automated systems maintain consistent dosing rates regardless of flow variations in the treatment process. This consistency is achieved through:

- Real-time flow measurement and adjustment

- Closed-loop control systems

- Automatic viscosity compensation

- Self-calibrating mechanisms

- Predictive maintenance alerts

Data Collection and Process Optimization

Modern PAM dosing system maintenance guide recommendations emphasize the value of data collection for continuous improvement. Automated systems typically provide:

- Historical dosing data for trend analysis

- Chemical consumption reports

- System performance metrics

- Alarm and event logging

- Remote monitoring capabilities

Essential PAM dosing system maintenance guide Practices

Regular maintenance is crucial for ensuring the long-term reliability and accuracy of PAM integrated dosing devices. A comprehensive maintenance program should address all critical components of the system.

Routine Maintenance Procedures

Following a structured maintenance schedule helps prevent unexpected downtime and maintains dosing accuracy. Key maintenance tasks include:

- Daily visual inspections of pumps and lines

- Weekly calibration checks

- Monthly filter changes and cleaning

- Quarterly lubrication of moving parts

- Annual comprehensive system review

Troubleshooting Common Issues

Even with proper maintenance, issues may arise that affect the cost-effective PAM dosing solutions performance. Common problems and their solutions include:

| Issue | Possible Causes | Recommended Actions |

|---|---|---|

| Inconsistent dosing | Worn pump parts, clogged lines, air bubbles | Inspect and replace worn components, purge air |

| Excessive noise | Cavitation, loose components, improper lubrication | Check suction conditions, tighten fittings, lubricate |

| Leakage | Damaged seals, loose connections, cracked lines | Replace seals, tighten connections, repair lines |

Exploring cost-effective PAM dosing solutions for Various Applications

While PAM integrated dosing devices represent a significant investment, there are numerous ways to optimize costs without compromising performance or reliability.

System Sizing and Configuration Options

Selecting the right system size and configuration is crucial for achieving cost-effective PAM dosing solutions. Considerations include:

- Current treatment capacity with room for expansion

- Modular designs that allow for future upgrades

- Multi-point dosing configurations for large systems

- Shared control systems for multiple dosing points

- Energy-efficient components to reduce operating costs

Lifecycle Cost Analysis

When evaluating PAM dosing system for industrial applications, it's important to consider total cost of ownership rather than just initial purchase price. Key cost factors include:

- Chemical savings from precise dosing

- Reduced labor requirements

- Lower maintenance costs

- Extended equipment lifespan

- Improved treatment efficiency

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP