- 1 Why the Screw Press Technology Matters in Sludge Dewatering

- 2 Five Operational Techniques to Boost Efficiency of Screw Press Sludge Dewatering

- 2.1 Technique 1: Optimising polymer dosing and flocculation

- 2.2 Technique 2: Controlling feed sludge characteristics (solids concentration, viscosity)

- 2.3 Technique 3: Adjusting screw speed, pitch and compression zone parameters

- 2.4 Technique 4: Maintaining equipment — cleaning screen basket, lubrication, wear parts

- 2.5 Technique 5: Monitoring key process parameters and implementing control strategy

- 3 Common Fault-Finding and Troubleshooting in Screw Press Sludge Dewatering Systems

- 4 Company Profile – How Anji Beifeite Yangzhou Qinxin Environmental Protection Technology Co., Ltd. Supports Efficient Screw Press Solutions

- 5 Conclusion

- 6 FAQ

In the realm of wastewater and sludge management, achieving optimal dewatering performance is a critical operational goal. For facility managers, process engineers and equipment operators, the efficient use of a Screw press for sludge dewatering is not only about selecting the right machine—but also about mastering operational techniques, monitoring performance parameters and resolving faults quickly. This article presents five proven operational techniques to boost dewatering efficiency and a detailed guide on common faults and how to troubleshoot them. We also provide insight into how Anji Beifeite Yangzhou Qinxin Environmental Protection Technology Co., Ltd., an industry-trade integrated enterprise engaged in research, development and sales of environmental protection equipment, including stacked screw sludge dewatering machines, PAM integrated dosing devices, sludge low-temperature drying systems and solid-liquid separators, supports clients across municipal, food, petrochemical, aquaculture, paper-making, leather, brewing, printing & dyeing, chemical, pharmaceutical and medical industries. With many years of practical experience and R&D in environmental equipment manufacturing, the company holds multiple patents and quality / environmental / occupational health & safety certifications, and serves export markets, especially in Southeast Asia.

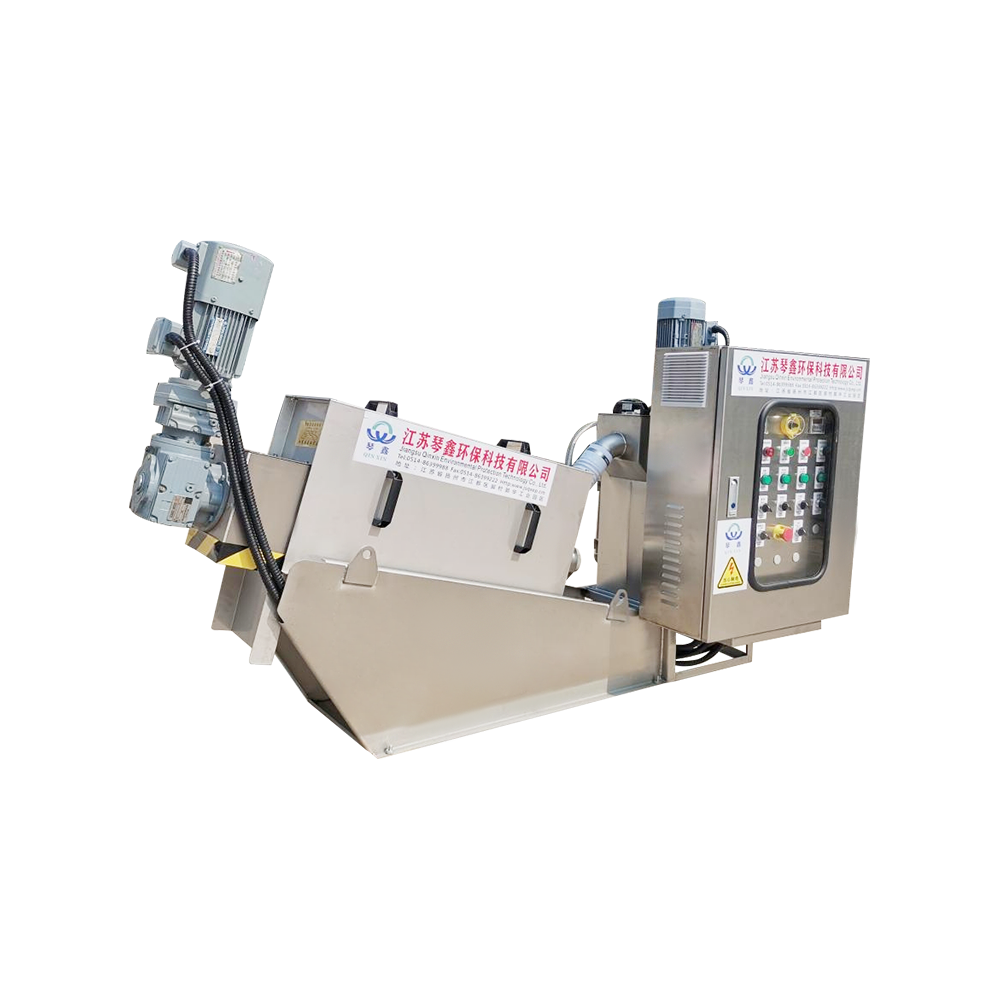

Industrial Fully Automatic Spiral Screw Sludge Dewatering Machine QXDL-131

Why the Screw Press Technology Matters in Sludge Dewatering

Principle of operation

The Screw press for sludge dewatering operates by conveying sludge through a slowly rotating screw inside a perforated or wedge-wire cylinder. As the sludge moves forward, the pitch reduces or the screw diameter increases, generating compression. Water drains out through the screen while the compressed solids exit as a dewatered cake. :contentReference[oaicite:0]

Advantages compared to other dewatering methods

Compared to a belt filter press or centrifuge, a screw press typically consumes lower energy, has simpler maintenance and can provide continuous operation.

Typical applications (municipal, industrial)

- Municipal wastewater treatment plants dealing with activated sludge.

- Food processing plants with wet by-products requiring solid–liquid separation.

- Chemical, paper-making, leather, printing & dyeing industries generating liquid sludge streams.

Five Operational Techniques to Boost Efficiency of Screw Press Sludge Dewatering

Technique 1: Optimising polymer dosing and flocculation

Better flocculation means larger flocs, faster drainage, and lower cake moisture. On the other hand, insufficient or excessive polymer dosing will reduce dewatering efficiency.

| Scenario | Effect on cake dryness |

| Optimised polymer dose | Lower moisture content, stable cake |

| Under-dosing or poor mixing | High moisture, turbidity in filtrate |

| Over-dosing polymer | "Glazed" cake, blocking screens, higher chemical cost |

Technique 2: Controlling feed sludge characteristics (solids concentration, viscosity)

Feed sludge with consistent solids concentration and moderate viscosity helps the screw press perform efficiently. Conversely, variable feed or very low solids content can reduce compression and slow drainage.

| Feed condition | Performance impact |

| Uniform solids concentration (e.g., ~2-5% DS) | Stable throughput, good dryness |

| Very low solids or high dilution | Longer residence time, lower cake % |

| High viscosity / fibrous sludge without conditioning | Screen clogging, lower recovery |

Technique 3: Adjusting screw speed, pitch and compression zone parameters

The mechanical design of the screw (pitch, diameter, interrupted flights) and operation speed directly influence the compression and dewatering efficiency. Proper adjustment leads to higher dryness; improper settings lead to lower cake solids or increased wear.

| Setting | Outcome |

| Reduced pitch toward discharge, moderate speed | High compression, higher cake solids |

| Large pitch, high speed | Less residence time, lower dryness |

| Excessive compression without condition change | Higher wear, risk of damage |

Technique 4: Maintaining equipment — cleaning screen basket, lubrication, wear parts

Regular maintenance ensures longevity and consistent performance of the screw press. Without it, downtime and poorer dewatering performance follow.

| Maintenance practice | Effect |

| Daily visual inspection & cleaning | Reduced blockages, stable operation |

| Monthly check of rings/screw wear | Maintains cake dryness, prevents leaks |

| Neglect maintenance | Higher moisture cake, frequent breakdowns |

Technique 5: Monitoring key process parameters and implementing control strategy

Continuous monitoring of cake dryness, torque, power consumption, feed rate and polymer dose helps detect deviations early and optimise operation. Without monitoring, the process drifts and performance degrades.

| What is monitored | Why it matters |

| Cake solids % / moisture | Primary performance indicator |

| Feed sludge flow & solids load | Affects residence time and compression |

| Polymer dose & mixing time | Flocculation quality |

| Motor torque / power draw | Detects abnormal load or screen blockage |

Common Fault-Finding and Troubleshooting in Screw Press Sludge Dewatering Systems

Fault 1: Poor cake dryness / high cake moisture

If cake moisture is higher than expected, check polymer dosing, feed concentration, and compression settings. On the contrary, when all parameters are correct, the cake dryness will stabilise at expected levels.

| Cause | Symptom |

| Incorrect polymer dose or poor mixing | Wet cake, cloudy filtrate |

| Feed solids too low or too variable | Low dryness, unstable cake |

| Screw pitch/wear issues | Lower compression, higher moisture |

Fault 2: Screen clogging or ring wear

A clogged screen or worn rings reduce drainage and cause equipment stress. Regular inspection avoids this; if neglected, the press performance drops.

| Issue | Effect |

| Screen apertures blocked | Reduced filtrate flow, increased pressure |

| Ring or screw wear | Leaks of sludge, reduced cake solids |

| No cleaning schedule | Frequent stoppages, higher maintenance cost |

Fault 3: Variable feed rate or polymer line blockages

Inconsistent feed or polymer supply leads to fluctuating performance. A stable and well-controlled feed system is the opposite scenario and ensures predictable output.

| Fault | Sign |

| Feed pump slip or rate variation | Inconsistent cake thickness, dryness variation |

| Polymer line clogging or settling | Poor flocculation, frequent re-start |

| Lack of monitoring | Undetected drift, performance sag |

Fault 4: Excessive power consumption or vibration

An unexpected rise in power draw or vibration often signals mechanical or hydraulic issues. Routine monitoring catches this; ignoring it leads to more severe problems.

| Indicator | Possible cause |

| Sudden increase in motor current | Screw jamming, blockage in screen |

| Vibration or noise | Bearing wear, misalignment |

| No prompt action | Secondary damage, increased downtime |

Fault 5: Inconsistent cake discharge or cake bridging

If the discharge of dewatered cake becomes erratic or bridges form in the outlet, production is hampered. Proactive design and operator attention avoid this; in contrast, ignoring leads to stoppages.

| Fault | Intervention |

| Cake hanging or bridging at outlet | Check screw end plate gap and adjust |

| Irregular cake size/shape | Inspect feed consistency and screw settings |

| No scheduled check | Frequent unplanned cleaning and downtime |

Company Profile – How Anji Beifeite Yangzhou Qinxin Environmental Protection Technology Co., Ltd. Supports Efficient Screw Press Solutions

Enterprise introduction

Anji Beifeite Yangzhou Qinxin Environmental Protection Technology Co., Ltd. is an enterprise that combines industry and trade and is committed to research and development and sales of environmental protection equipment. The company is mainly engaged in stacked screw sludge dewatering machines, PAM integrated dosing devices, sludge low-temperature drying systems, solid-liquid separators, and other sewage treatment equipment, serving municipal, food, petrochemical, aquaculture, paper-making, leather, brewing, printing & dyeing, chemical, pharmaceutical, medical and other industries.

Main products and serving industries

- Stacked screw sludge dewatering machines

- PAM integrated dosing devices

- Sludge low-temperature drying systems

- Solid-liquid separators

- Serving industries: municipal wastewater, food processing, petrochemical, aquaculture, paper, leather, brewing, printing & dyeing, chemical, pharmaceutical, medical.

R&D, certifications and export markets

The company, based on many years of practical experience and R&D in production of environmental protection equipment, holds multiple patents and quality management system certifications, environmental management system certifications, and occupational health & safety management system certifications. The enterprise management process has won the trust of the majority of customers. Focusing on high-grade and high-end market, annual production of equipment mainly exported to Southeast Asian countries, has become an important supplier of sewage treatment equipment in China.

Why choose them for stacked screw sludge dewatering solutions

Their strong technical force, advanced service awareness, strict regulations and dedicated team provide the foundation for reliable equipment supply and after-sales support. For clients seeking to optimise their sludge dewatering operations using a Screw press for sludge dewatering and the long-term support, partnering with this company offers operational confidence and high performance.

Conclusion

Optimising a Screw press for sludge dewatering requires attention to both the operational techniques and the routine troubleshooting practices. By implementing the five key operational techniques—polymer and flocculation control, feed characteristic management, mechanical parameter adjustment, maintenance routines and process monitoring—and by staying alert to common faults such as poor cake dryness, screen clogging, feed variability, abnormal power consumption and cake discharge issues, you can significantly improve your dewatering efficiency and reduce downtime. The expertise of Anji Beifeite Yangzhou Qinxin Environmental Protection Technology Co., Ltd. in stacked screw sludge dewatering machines and allied equipment makes them a solid partner for industrial or municipal sludge dewatering projects. Put simply: better process control + proactive maintenance = higher cake solids + lower disposal cost.

FAQ

- Q1: What polymer dosage range is recommended for screw press sludge dewatering?

A1: Although the optimal dosage depends on sludge type, feed solids and flocculation system, many applications find an effective range after jar tests. The key is to adjust until cake dryness maximises and filtrate turbidity minimises. - Q2: What feed solids concentration should I aim for when using a screw press?

A2: A stable feed solids concentration (for example around 2-5 % DS) helps performance, but many systems handle lower or higher concentrations. If feed is too dilute or too variable, throughput and cake dryness may suffer. - Q3: How often should maintenance be conducted on the screw press equipment?

A3: Daily visual inspections and tank cleaning, monthly checks of wear parts and screen condition, and annual review of operating conditions and parts replacement are good practice. - Q4: What are signs that the screw press is not performing optimally?

A4: Indicators include an increase in cake moisture, higher filtrate turbidity, increased motor current or vibration, frequent downtime or inconsistent cake discharge. Monitoring helps spot these early. - Q5: Can a screw press be used for varying industries and sludge types?

A5: Yes. A Screw press for sludge dewatering is versatile and can handle municipal, industrial (food, chemical, paper, leather) sludge streams, provided that it is correctly specified and operated. It is especially favourable where energy efficiency and smaller footprint are priorities.

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP